Material Data

Performance Materials

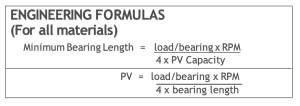

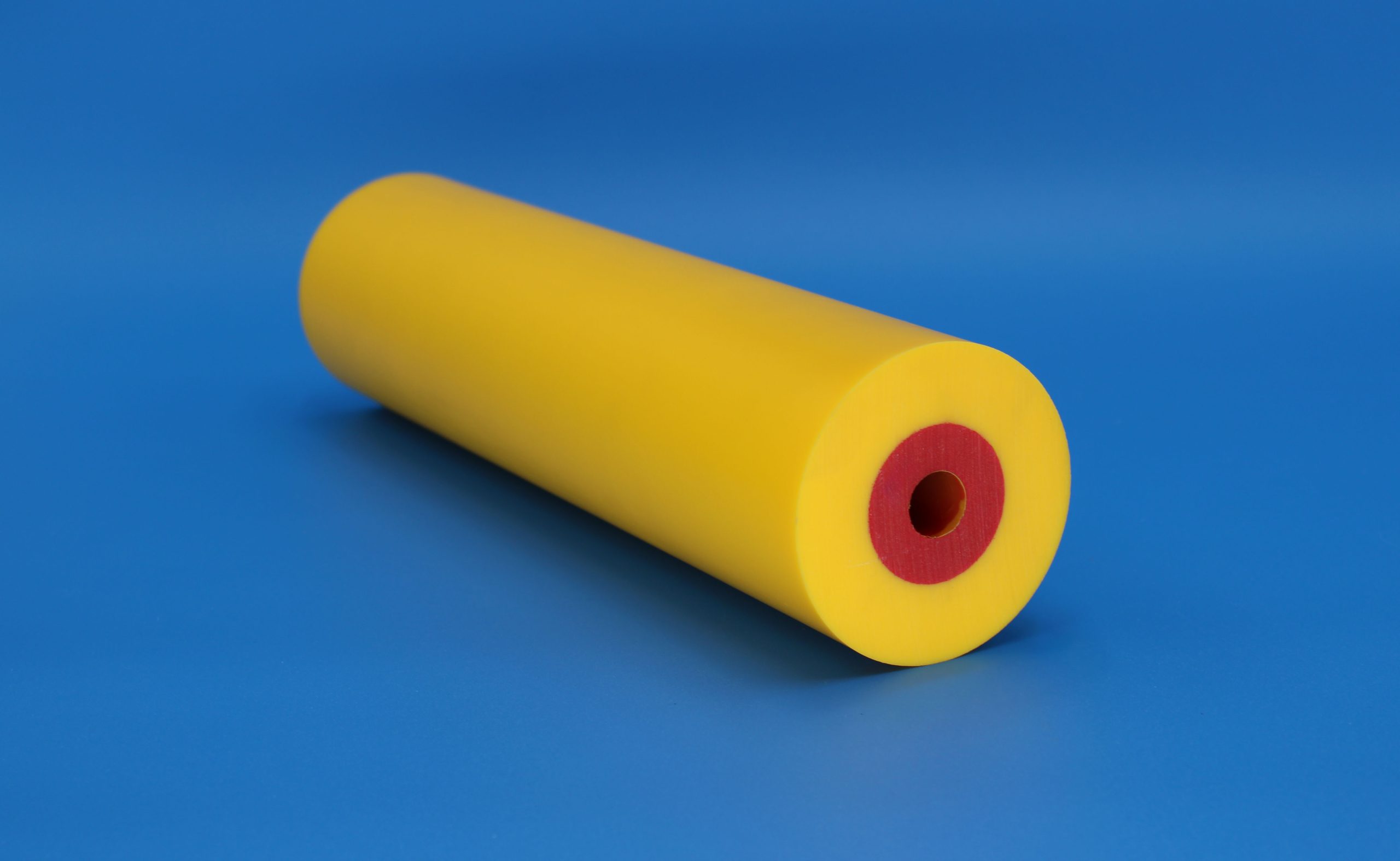

POBCO-B® HARDWOOD (NO-STATIC BUILDUP) POBCO-B lubricant-impregnated hardwood bearings, wearstrips and components often provide the best overall service of our various bearing materials. These natural fiber bearings are 100% filled with a blend of fluid lubricants. They render a greater speed/ load capability and have a lower wear rate factor than many plastics. This material is suitable for indirect contact only in the food and beverage industry. (100% Dielectric)

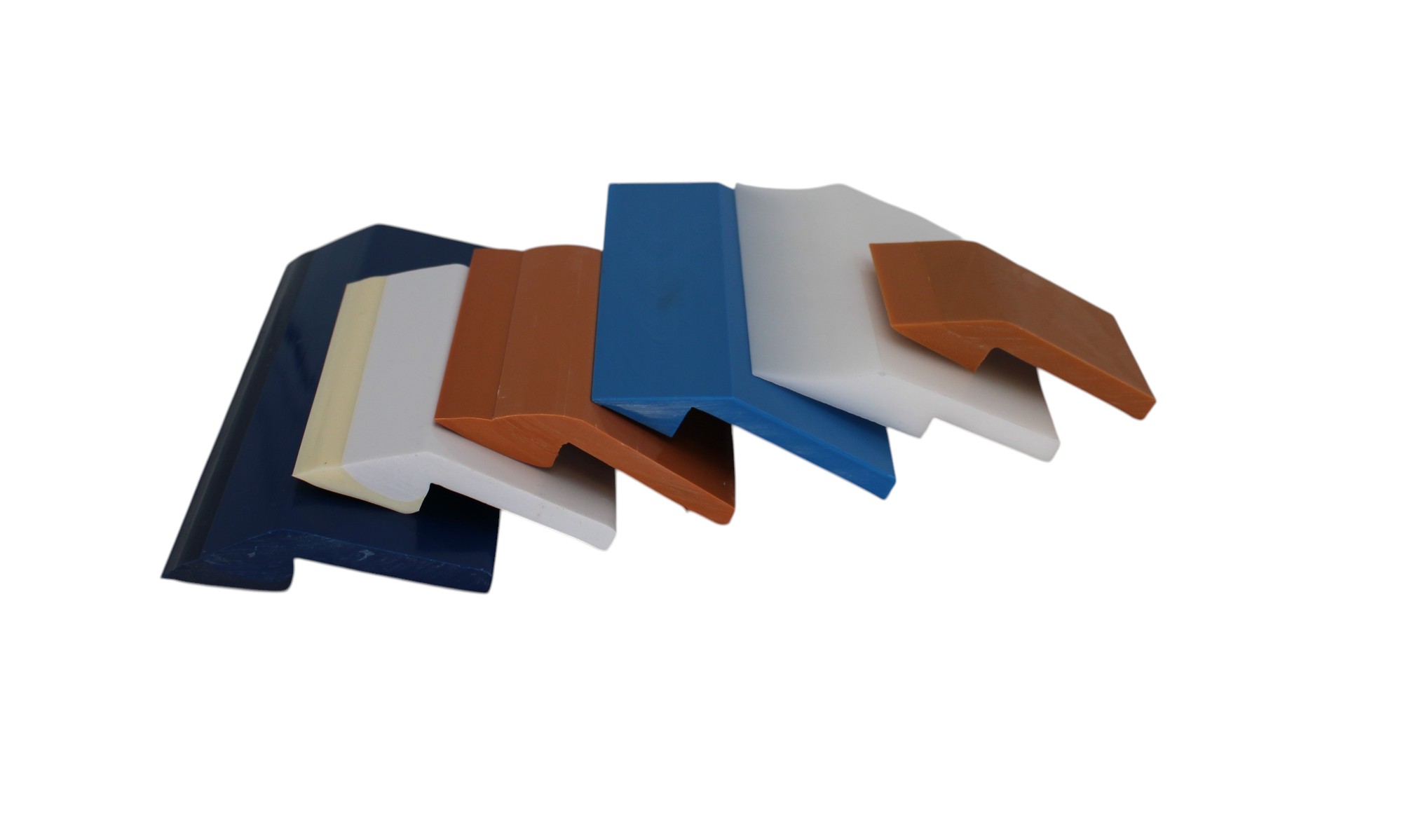

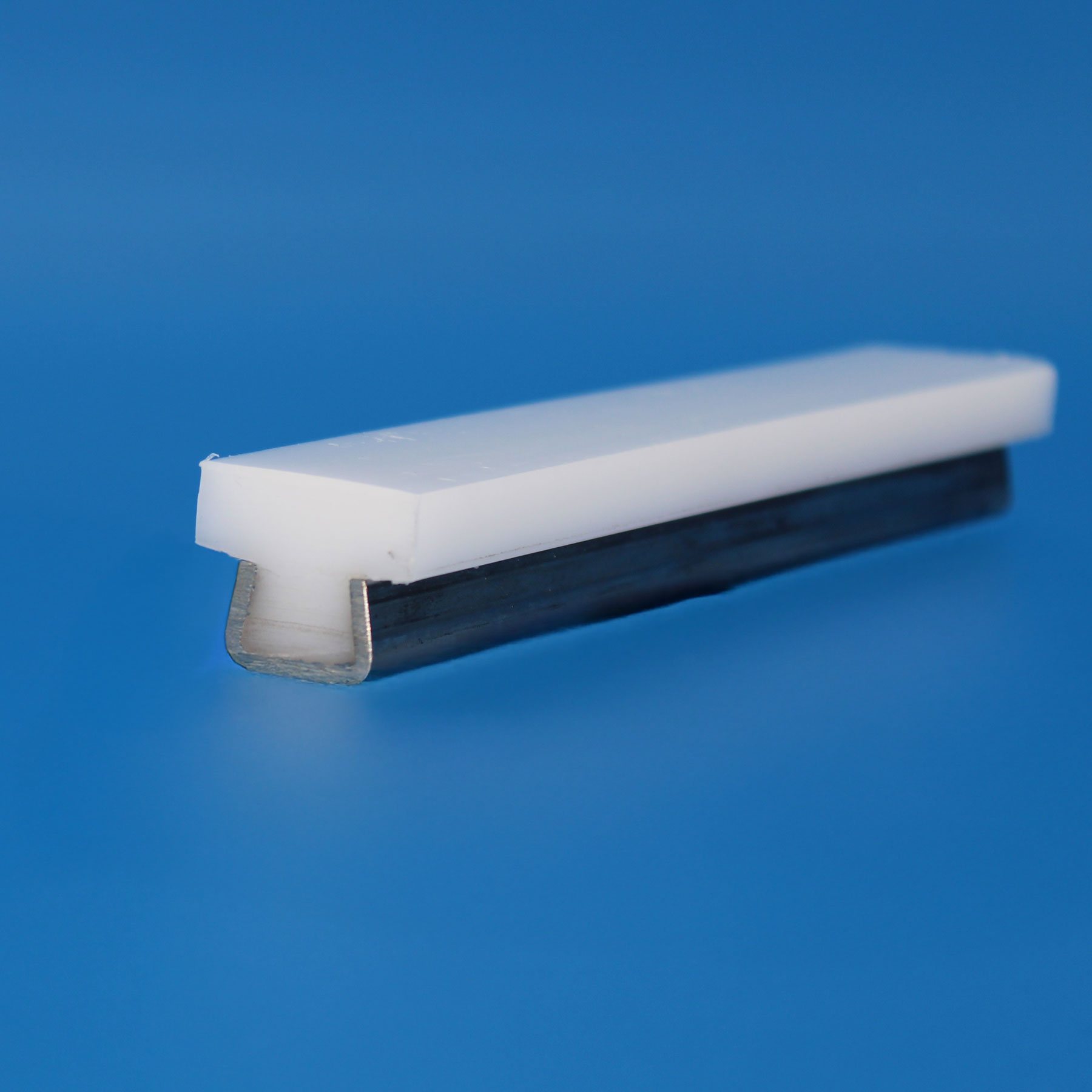

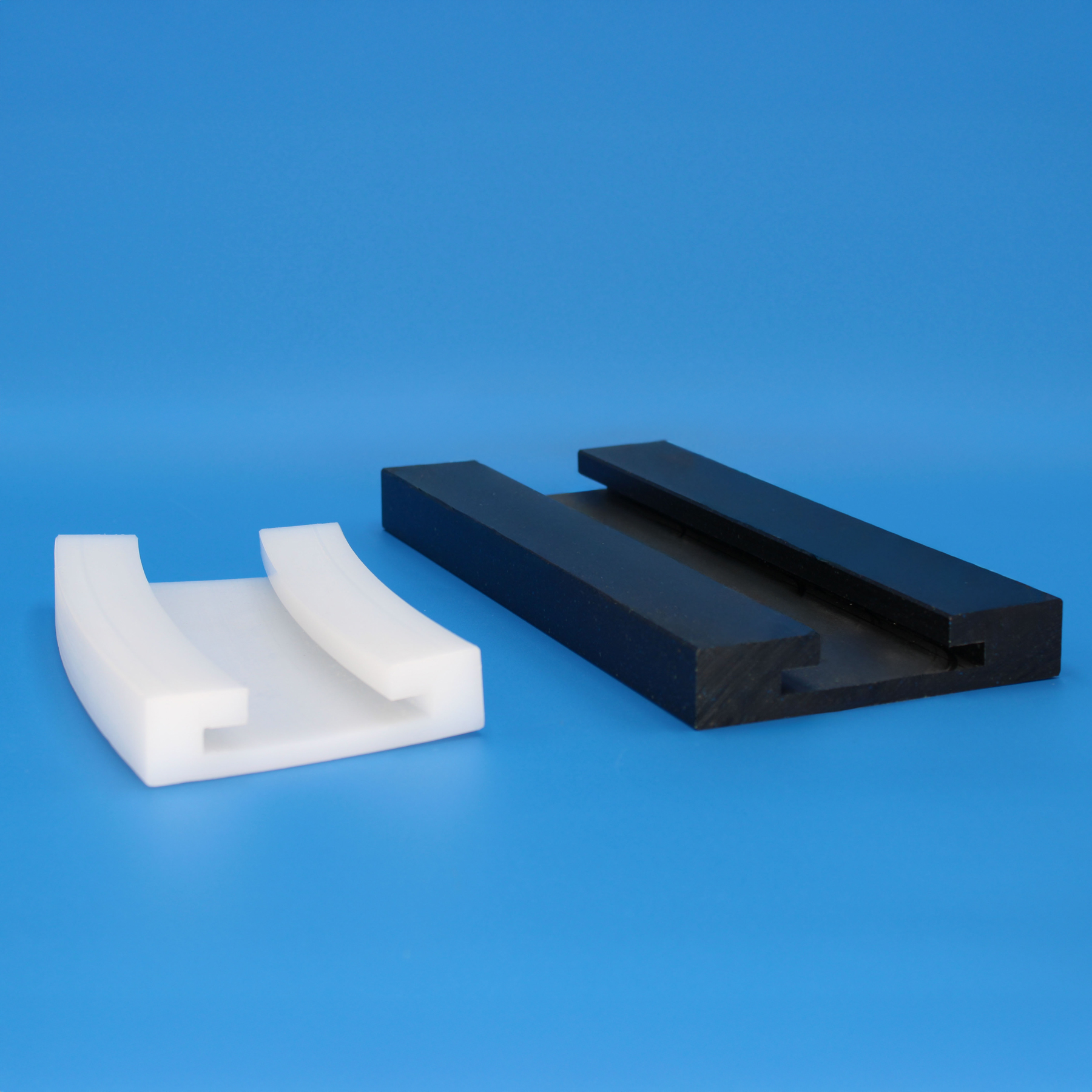

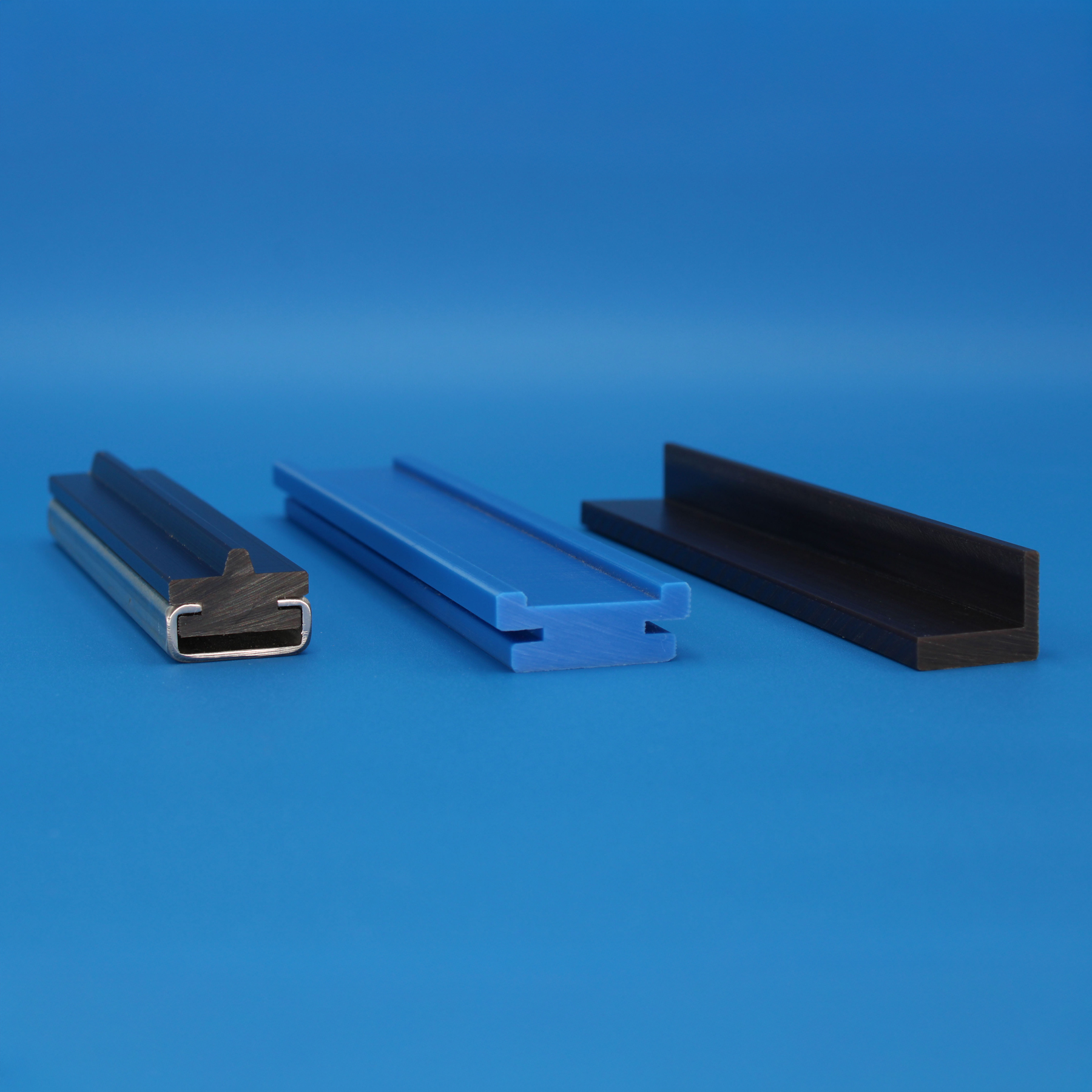

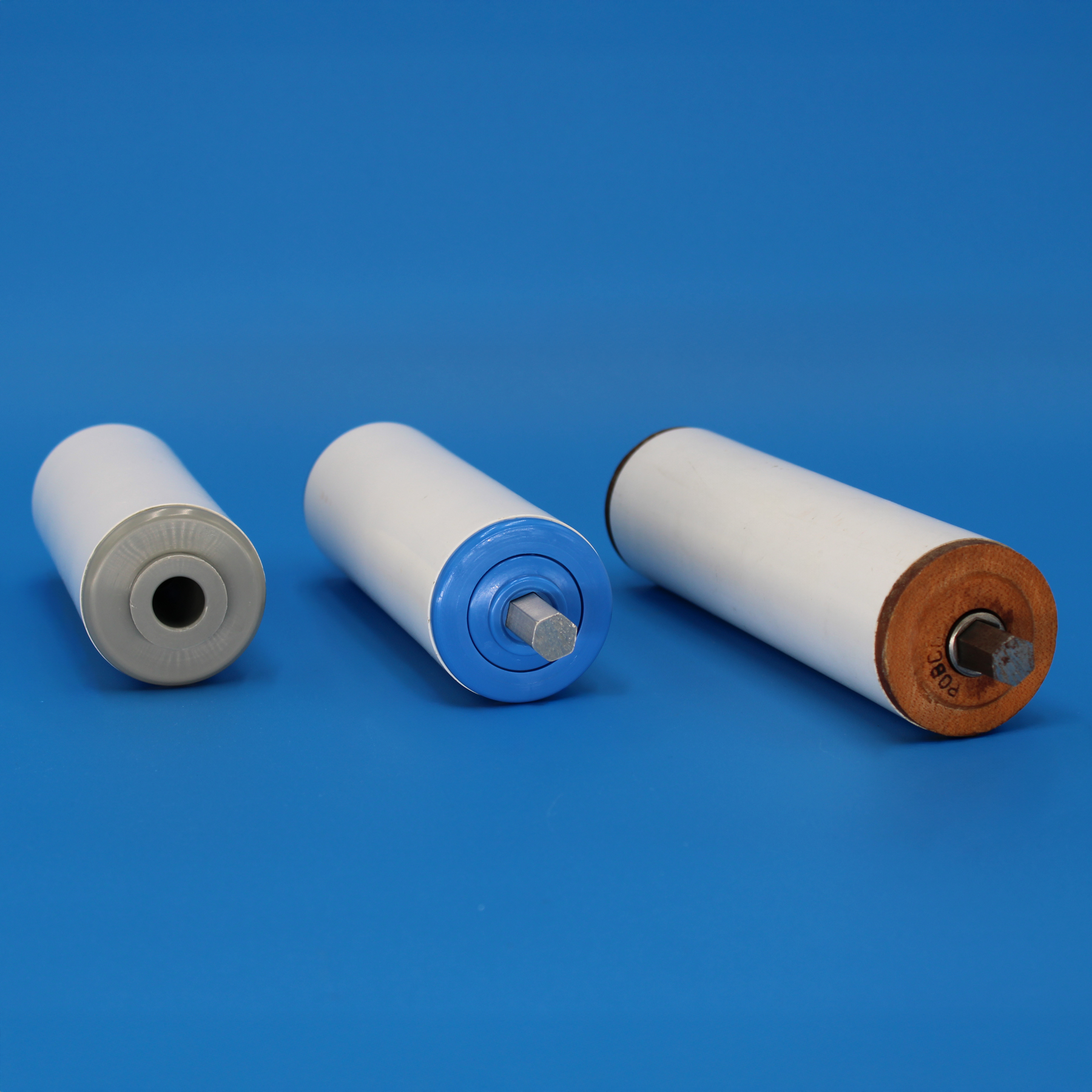

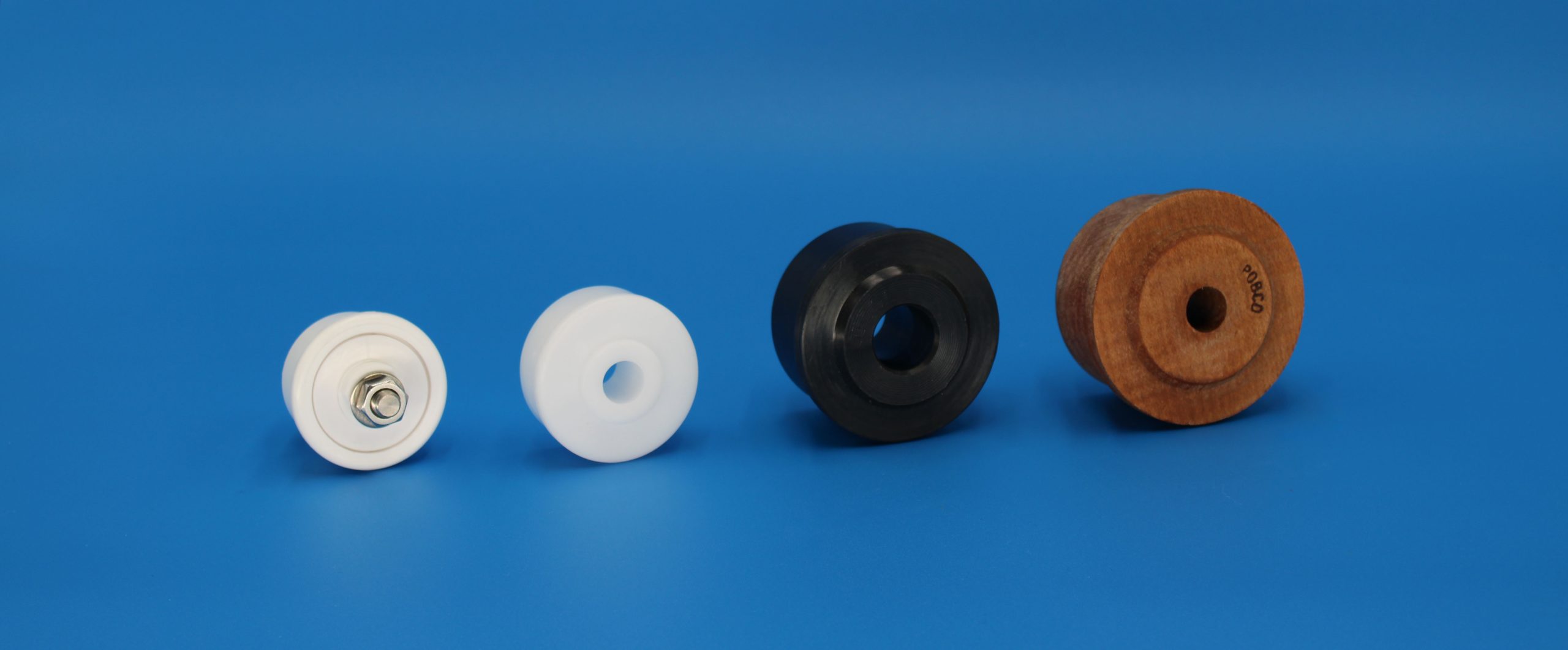

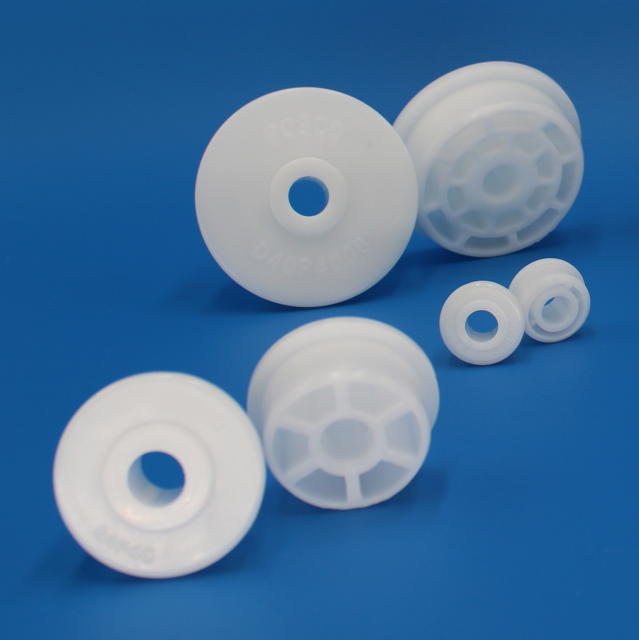

POBCO UHMW (RATED FOR 180 DEG F) AND POBCO HI-TEMP UHMW (RATED FOR 275 DEG F) Both the UHMW and Hi-Temp UHMW bearings and wear strips are made from Ultra High Molecular Weight Polyethylene (UHMW). This material is widely used to reduce friction from metal on metal contact. Applications are often in the presence of abrasive particles, wet environments, and will tolerate exposure to many chemicals. It is FDA and USDA approved for direct contact with food products. (special blends and colors available)

POBCO PLUS® POBCO Plus bearings and components are manufactured utilizing a food grade fluid lubricant united with UHMW plastic. This product was developed to retain the basic properties of UHMW while creating a plastic bearing material which reduces the coefficient of friction and wear rate factor. POBCO Plus meets all official requirements for use in the food and beverage industry. Reduces drag and friction up to 40%.

POBCO BLUE UXC UHMW is primarily used as Guide material for Table Top and Roller Chain applications. This blend of UHMW has a coefficient of friction of 50% to 75% less than standard UHMW when used with Acetal, PET and Steel Table Top Chain. Other characteristics include: outstanding dry-running properties, FDA compliant, noise reducing, and eliminates the slip-stick effect (back-sliding).

POBCO BLUE “AW” is our lowest coefficient of friction formula. Lubricant is uniformly dispersed for continued lubricity throughout the cross section. Reduces tendency to “stick-slip” under intermittent dynamic loads. Ideal for belt guides, roller chain guides, and table top applications and is FDA compliant. Color: Royal blue

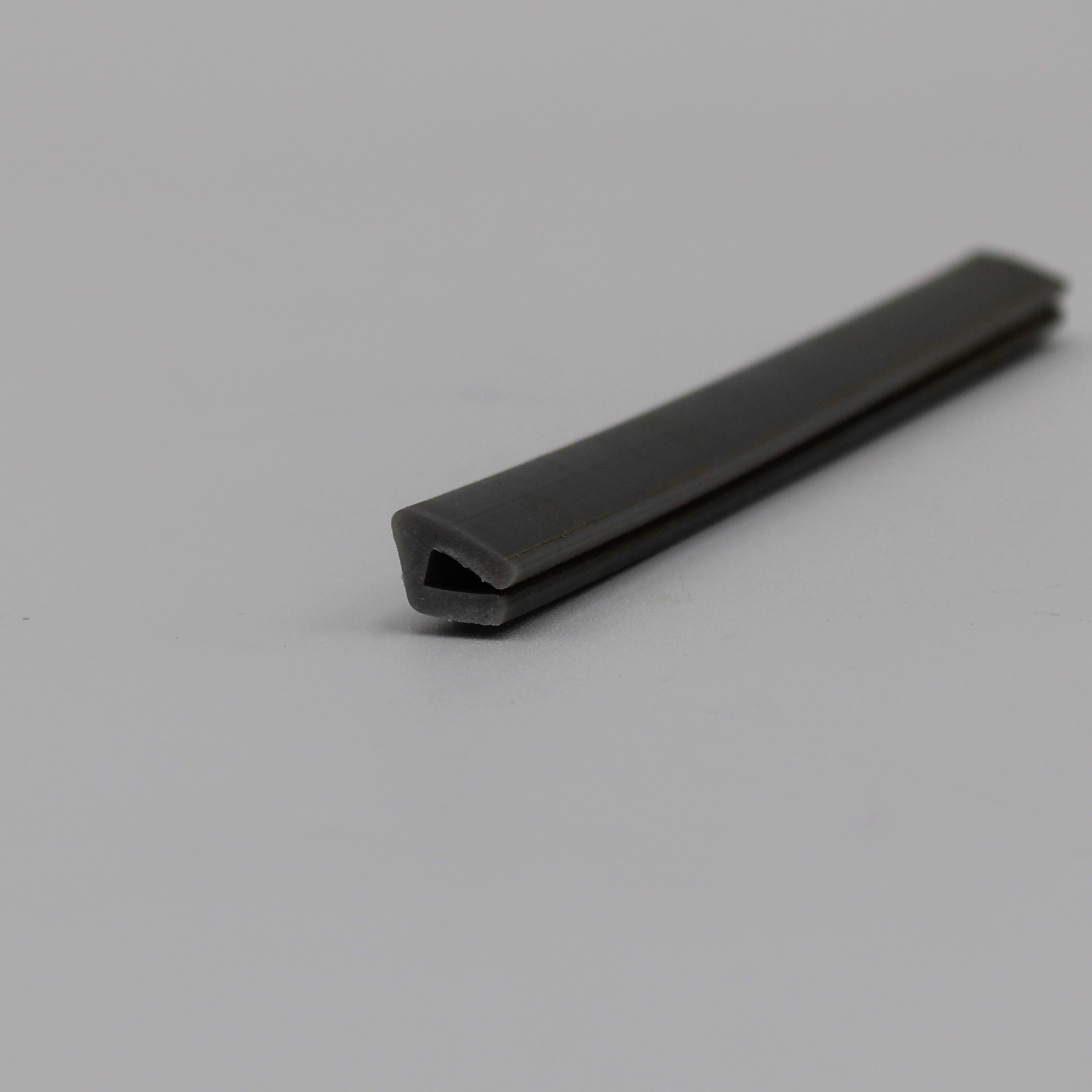

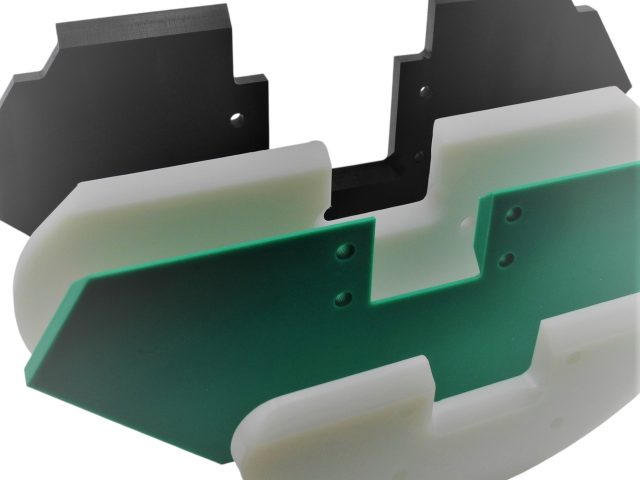

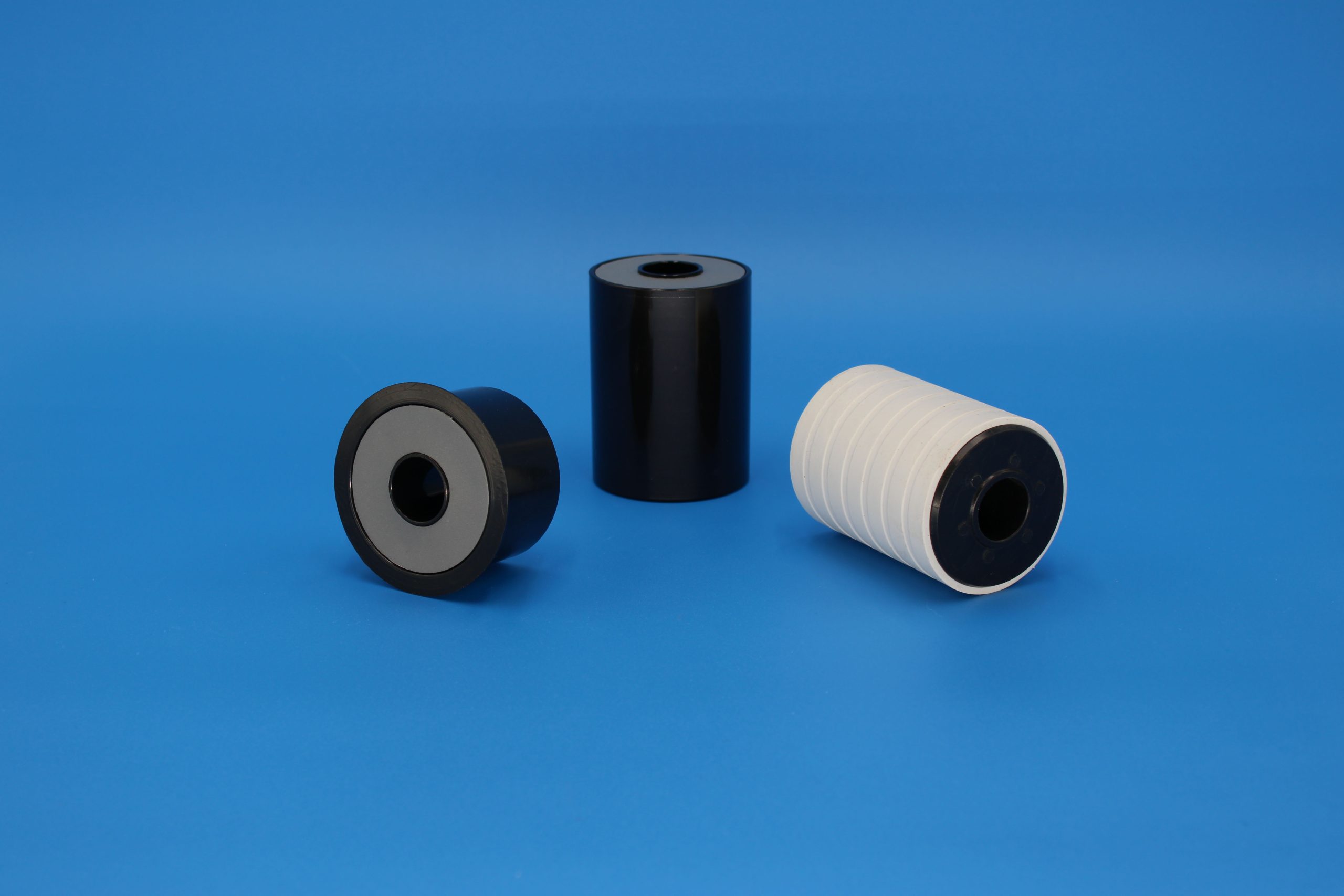

POBCO STATIC-DISSIPATIVE /ANTI-STATIC MATERIALS POBCO offers several plastics materials with varying degrees of static-reduction capabilities, including black UHMW. These materials can help solve electrical discharge and dirt/ grime attraction problems. These materials offer excellent wear and bearing properties and are available in many standard and custom shapes and sizes including Guide Rails, Wear Strips, Clip-Ons, Bearings and Conveyor Rollers. Minimums may apply. These plastic materials are not FDA/USDA compliant. Static-Dissipative Range: Surface Resistivity 105 – 109 ohms/square Anti-Static Range: Surface Resistivity 109 – 1014 ohms/square

POBCO HI-WEAR UHMW 33% more wear resistant than unfilled UHMW. Excellent for use as Chain Guides, Bottle-Neck Guides, Liners and in Waste Handling applications. Not FDA/USDA compliant.

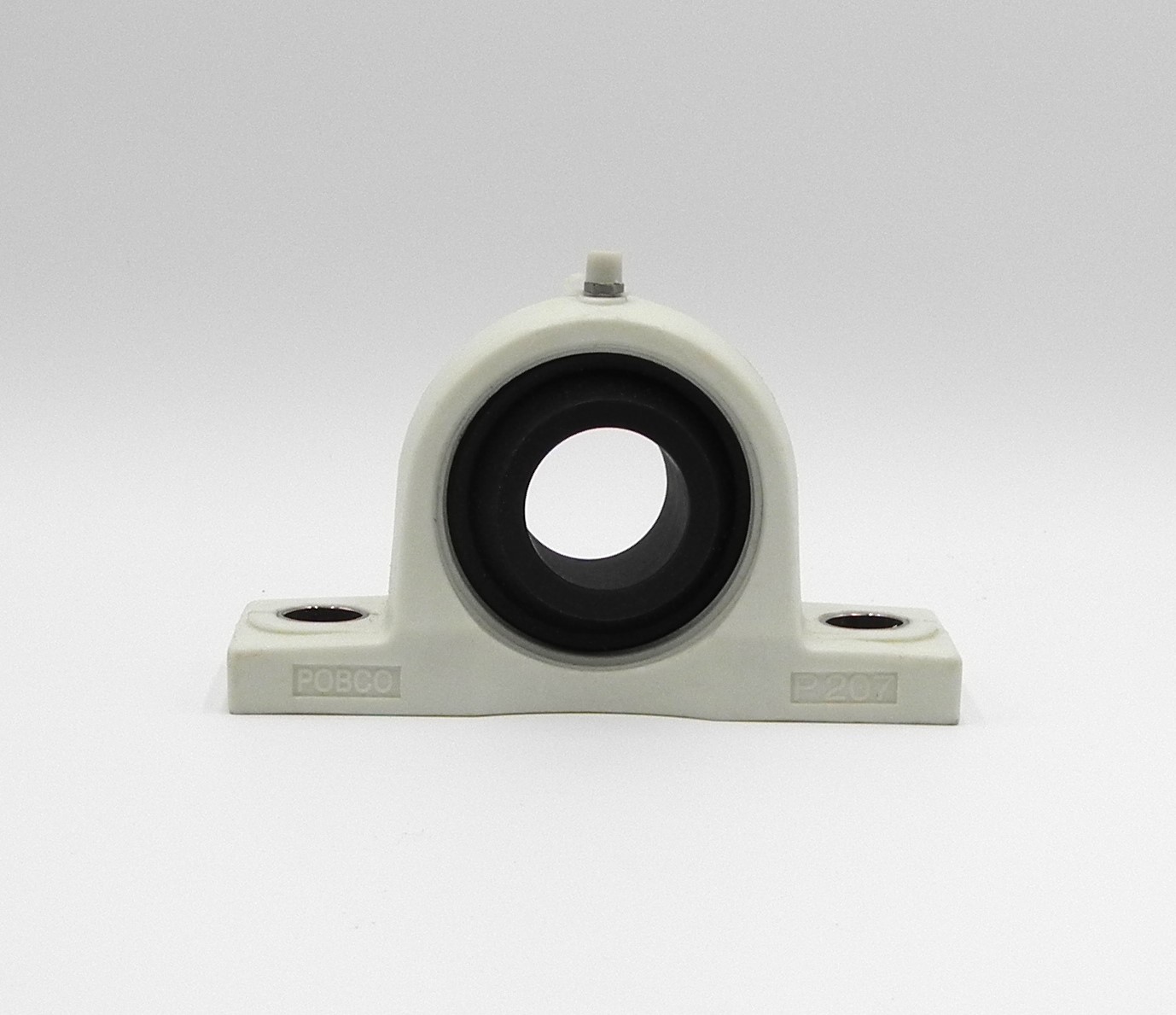

ACETAL (DELRIN®) POBCO molded Delrin bearings and components find their primary usage in light to medium duty applications. POBCO machined Delrin bearings can be made for heavier duty applications. Our Delrin equipped rollers have low overall cost while affording long service life. Acetal is FDA, USDA compliant. Acetal is more resistant to hot steam cleaning than UHMW.

POBCO NYWEAR (FDA & NON FDA MATERIALS) POBCO Nywear bearings and components are especially suited for high heat (230ºF+) material handling applications. This fluid lubricant-filled plastic renders exceptional wear and abrasive resistant capabilities with a low heat build up. High PV limit.

POBCO NYLON MD (NYLATRON GS®) POBCO Dry Lubricant-Filled Nylon bearings and components are preferred for heavy load, high speed operations up to approximately 220ºF operating temperatures. Color is charcoal gray/black.

RULON® LR (NON FDA) Specially compounded forms of PTFE Fluropolymer used as a bearing material which requires no lubrication and is capable of performing under severe temperature and corrosive conditions. The operating temperature ranges from – 400º to +550ºF.

RULON® 641 white plastic is approved for use in the Food, Drug, and Chemical Industry. This material is common for high heat applications up to 550ºF. It’s friction decreases rapidly with increasing load. Other grades of Rulon also are available with higher/lower PV values for nonfood applications.

POBCO PTFES Highly chemically resistant, with operating temp. range of 450º – 550ºF depending on the additive. High PV ratings and some food grades available.

POBCO POBLON is a Hi-Temp (500ºF), proprietary blend of PTFE.

POBLON is FDA/USDA compliant. Used in food & pharmaceutical applications such as ovens, fryers, proofing & curing operations. A less expensive alternative to Rulon 641. Color is off-white.

PEEK® High Temp. 480ºF, High PV limits, low coefficient of friction excellent chemical & wear resistant.

ERTALYTE® PET-P (POLYESTER) Excellent dimensional stability, less moisture absorption & better wear resistance than many plastics, operates at 210ºF continuously, FDA compliant, weather resistant. Good chemical and abrasion resistance.

POBCO DRY WEAR DRY LUBE FILLED UHMW Black color Non-FDA. Improved coefficient of friction and anti-static properties. Better in dusty applications: less build-up. UV stabilized.

Metal detectable Acetal and UHMW now available. Please inquire for more details. It is the responsibility of the user to test and approve the metal detection of this product due to variations in metal detection systems and required sensitivity settings.

Properties of POBCO Materials

|

ENGINEERING DATA |

POBCO-B

HARDWOOD |

UHMW | LUBE-FILLED UHMW PLUS® |

REPRO UHMW |

(7) HI-TEMP. UHMW |

(13) HI-WEAR UHMW |

DRYWEAR UHMW |

(11) NYWEAR | NYLON | (10)

NYLON MD |

|

| CODE LETTERS | B | U | P | UR | UH | CP | DW | NW | N | MD | |

| P.V. Cap psi-fpm (1) | 12,000 | 2,000 | 12,000 | 2,000 | 2,000 | 2,300 | 4,000 | 16,000 | 2,500 | 3,500 | |

| Max. Surface Speed fpm | 500 | 100 | 300+ | 100 | 100 | 100 | 150 | 150 | 100 | 150 | |

| Static Load Cap. psi | 1,000 | 1,000 | 600 | 900 | 1,000 | 1,000 | 1,000 | 1,000 | 1,000 | 1,000 | |

| Service Temp. Range (2)oF | 180 | 180 | 165 | 180 | 275 | 200 | 180 | 230+ | 220 | 220 | |

| Coef. of Friction Ave. | .09 | .15-.20 | .06-.12 | .15-.20 | .15-.20 | .16-.18 | .15 | .15 | .19 | .17 | |

| Abrasion Resistance (3) | 1-3 | 1-2 | 1-2 | 1-2 | 1-2 | 1 | 1-2 | 3 | 3 | 3 | |

| Dim. Stability in Water | Fair | Exc. | Exc. | Exc. | Exc. | Exc. | Exc. | Good | Fair | Fair | |

| USDA/FDA Compliant | Indirect | yes | yes | no | yes | no | no | yes* | yes | no | |

| Chemical Resistance at 73o F* | |||||||||||

| Acid Weak | A | A | A | A | A | A | A | A | A | A | |

| Acid Strong | L | L | L | L | L | A | L | U | U | U | |

| Alkalies Weak | A | A | A | A | A | A | A | A | A | A | |

| Alkalies Strong | L | A | A | A | A | A | A | A | A | A | |

| Hydrocarbon Aromatic | – | L | L | L | L | A | L | A | A | A | |

| Hydrocarbon Aliphatic | – | A | A | A | A | A | A | A | A | A | |

| Ketones | – | A | A | A | A | A | A | A | A | A | |

| Ethers | – | A | A | A | A | A | A | A | A | A | |

| Alcohols | – | A | A | A | A | A | A | A | A | A | |

| Inorganic Salt Solution | A | A | A | A | A | A | A | A | – | A | |

| Continuous Sunlight | A | U** | L | L | L | A | L | L | L | L | |

| Standard Color | Brown | White | Grey/Brown | Black/Green | White | Black/Green | Black | Natural | White/Grey | Black | |

| Low Temp oF* | – | -200 | – | -200 | – | – | -10 | -10 | -10 | ||

| ENGINEERING DATA | ACETAL DELRIN® |

(8) ACETAL AF |

VIRGIN PTFE |

GLASS FILLED PTFE |

POBLON | RULON® 641 | RULON® LR BEARING GRADE |

ERTALYTE® | UNFILLED PEEK |

| CODE LETTERS | D | DT | T | GT | TM | RF | RB | YT | PK |

| P.V. Cap psi-fpm (1) | 2,000 | 8,000 | 1,000 | 10,000 | 10,000 | 10,000 | 10,000 | 2,800 | 14,000 |

| Max. Surface Speed fpm | 100 | 150 | 100 | 400 | 400 | 400 | 400 | 125 | 100 |

| Static Load Cap. psi | 2,000 | 2,000 | 400 | 800 | 1,000 | 1,000 | 1,000 | 2,000 | 6,000 |

| Service Temp. Range (2)oF | 180 | 200 | 450 | 500 | 500 | 550 | 550 | 210 | 480 |

| Coef. of Friction Ave. | .22 | .08-.14 | .06-.15 | .10-.13 | .10-.30 | .10-.30 | .15-.25 | .20 | .20 |

| Abrasion Resistance (3) | 5 | 1-2 | 5 | 1-2 | 1-2 | 1-2 | 1-2 | 3 | 1-2 |

| Dim. Stability in Water | Good | Good | Exc. | Exc. | Exc. | Exc. | Exc. | Good | Exc. |

| USDA/FDA Compliant | yes | maybe | yes | no | Yes | yes | no | yes | yes |

| Chemical Resistance at 73oF* | |||||||||

| Acid Weak | A | S | A | A | A | A | A | A | A |

| Acid Strong | U | U | A | A | A | A | A | L | L |

| Alkalies Weak | A | A | A | A | A | A | A | A | A |

| Alkalies Strong | U | U | A | A | A | A | A | U | A |

| Hydrocarbon Aromatic | A | A | A | A | A | A | A | A | A |

| Hydrocarbon Aliphatic | A | A | A | A | A | A | A | A | A |

| Ketones | A | A | A | A | A | A | A | L | A |

| Ethers | A | A | A | A | A | A | A | A | A |

| Alcohols | A | A | A | A | A | A | A | A | A |

| Inorganic Salt Solution | – | A | A | A | A | A | A | A | A |

| Continuous Sunlight | U | L | A | A | A | A | A | A | – |

| Standard Color | White | Brown | White | White | White | White | Maroon | White | Beige |

| Low Temp oF* | -40 | -40 | -200 | -200 | -400 | -200 | -200 | – | – |

#1 At Room Temperature

#2 At Low PV Levels

#3 Rating 1 (Excellent) to 5 (Fair)

#5 A=Acceptable L=Limited U=Unacceptable

#7 Thermal Expansion Is Up To 25% Less Than Normal

UHMW with extended wear life

#8 PTFE-Filled Acetal

#10 Moly-Filled Nylon

#11 Lube-Filled Nylon – Bearing Grade Green, FDA

Compliant Off White

#12 Green & Black Reprocessed UHMW

#13 33% More Wear Resistant than unfilled UHMW

POBCO-B Wood Materials and POBCO Plastics

Bearing Clearances

POBCO bearings are normally furnished with an installed clearance between the bearing and its journal, as shown in the table below. This provides the proper running clearance under actual operating conditions. Bearings also can be furnished with no clearance when the user desires to ream after installation in housing. Reaming has no effect on the self-lubricating action of POBCO non-metallic bearings.

| SHAFT DIA. |

CLEARANCE |

|||

| BEARING OPERATING CONDITIONS |

ROLL END OPERATING CONDITIONS |

|||

| DRY | WET | DRY | WET | |

| to 1/2” | .002-.010 | .010-.030 | .015-.030 | .015-.045 |

| 1/2” to 1” | .004-.015 | .015-.040 | .015-.030 | .030-.055 |

| 1” to 1-1/2” | .006-.020 | .025-.050 | .015-.030 | .040-.060 |

| 1-1/2” to 3” | .010-.025 | .030-.060 | ||

| 3” or larger | .015-.030 | .030-.070 | ||

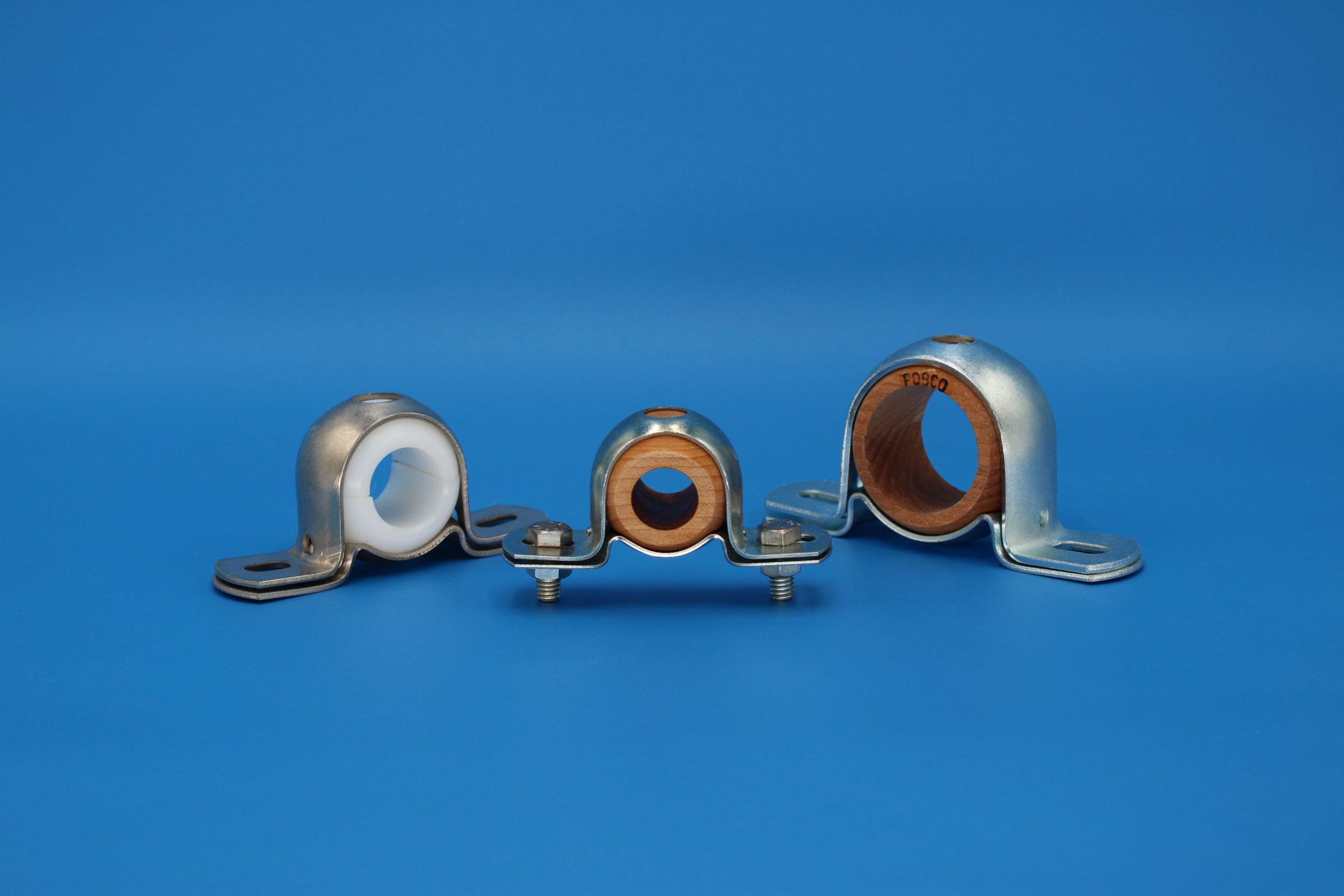

Press Fits

POBCO sleeve, flange and roll end bearings are normally furnished with oversize outside diameters to ensure firm retention in their housings, as shown in the table. The leading edge of the housing must be chamfered to prevent shearing the outside diameter of the bearing during installation.

Normal bearing tolerances are shown in the following table. Closer tolerances are available.

| Nominal OD | Press Fit |

| to 1/2” 1/2” to 1-1/2” 1-1/2” to 3” 3” and larger |

.003-.006 .004-.008 .005-.010 .006-.012 |

Required Material Information

(For Bearings, Rectangular Wear Strip, Curved Wear Strip and Chain & Cable Guides) To signify POBCO materials add code letters before the first hyphen in the part number.

Examples:

- For POBCO-B (lubricant-filled hardwood) add B

- For POBCO Plus (fluid lube-filled UHMW) add P

- For POBCO UHMW add U

Required Bearing Information

To complete the bearing part number, indicate the bearing clearance by adding the appropriate suffix from the table below.

D-Dry operating condition clearance (for POBCO-B only) W-Wet operating condition clearance (for POBCO-B only)

N-No clearance (for reaming at installation)(for all materials)

Examples:

- Sleeve bearing 1/2” x 3/4” x 1-1/4” for dry operating conditions: SLB-0812020-D

- Flange bearing 5/8” x 1” x 1-1/2” no clearance (for installation): FLU-1016024-N

- Two piece spherical bearing, 62mm sphere, 1-1/4” shaft, wet operating conditions: PSBB-206228-TP-W

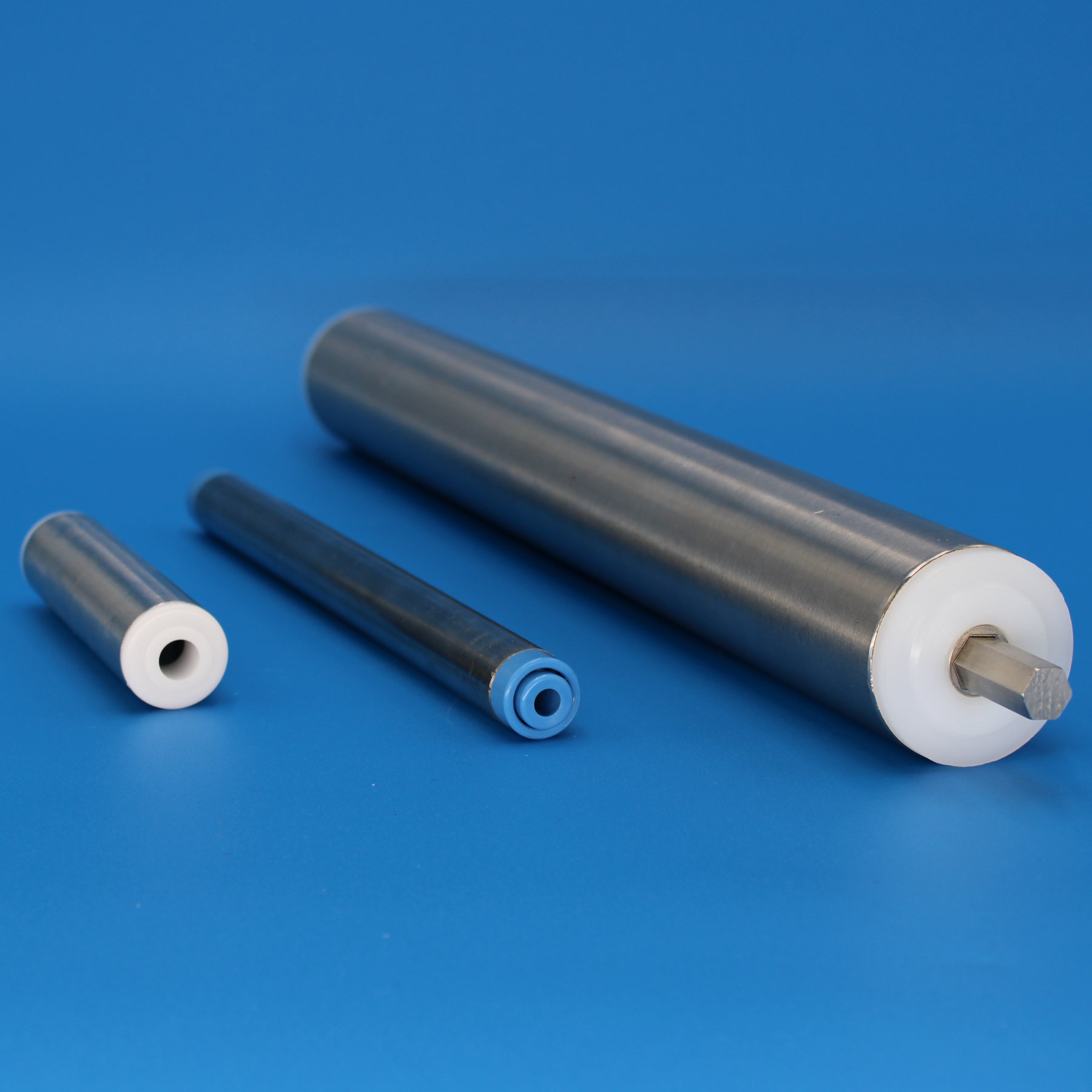

Roll End Bearings

To complete the roll end bearing or part number, add the shaft size in sixteenths (two digits) followed by the bearing clearance suffix. (1/2” shaft = 08, 3/4” shaft = 12)

Examples:

- Standard roll end bearing for 2-1/2” diameter 16 gauge tubing with 5/8” shaft: STP-40T16-10

- Blind-bore roll end bearing for 2” schedule 40 PVC pipe with 9/16” shaft operating in a wet condition: BLB-32P40-PVC-09W

Wear Strip Tolerances

POBCO UHMW, POBCO plus, and POBCO-B Hardwood

| Normal Commercial Tolerances Thickness |

Normal Machined Tolerances Thickness |

| 1/8”-3/16” +/- 15% 1/4”-3/8” +/- 10% 1/2” & over +/- 10% Width: +/- .030” Length: -1/2”+1” |

1/8”-3/8” +/- .020” 1/2” & over +/- .010” Width: +/- .010” Length: +/- .030 |

CLOSER TOLERANCES ARE AVAILABLE. FOR OTHER MATERIAL TOLERANCES, PLEASE INQUIRE. PLEASE SPECIFY COMMERCIAL OR MACHINED OR OTHER TOLERANCES.

Required Wear Strip Information

To complete the wear strip part number, add the length in inches as shown by the examples below:

- Rectangular wear strip 1/2” thickness x 2” width x 60” length: WSB-0832L60

- Chain Guide, Profile 2, 2060 chain, 120” length:P2P-2060L120

Allowances must be made to eliminate the possibility of binding caused by machine and material expansion when designing wear strip.

Wood and Engineering Data

POBCO-B Physical Properties (Lubricant-Filled Hardwood)

| Density (lbs/in3) Coefficient of Friction Temperature Range Specific Gravity Lubricant Content by Weight Load Weight (continuous duty) |

.038 .07-.112 -50o to 180o 1.2 40% 1000 psi |

Tensile Strength Permanent Deformation (7500 psi compression) Coefficient of Thermal Expansion (per oF) PV Factor (continuous duty) Wear Rate Factor |

1100 psi .005 set 4.3 x 10-6 12,000 psi-fpm <0.1×10-10 (inch) PV x hr. |

POBCO-B Bearings and Wear Strips

Our exclusive lubricant blend is impregnated into 100 percent of the hardwood, producing POBCO-B material from which the bearings & wear strips are manufactured. The lubricant on the bearing surface provides a low friction film for initial start-up. During operation, additional lubricant is drawn to the bearing surface in a controlled flow to maintain a continuous film between the journal or chain and the bearing. The flow constantly adjusts itself based on load, speed, and the requirements of the operation. When motion ceases, the bearing reabsorbs the lubricant. Reaming does not seal off the self- contained lubricants.

POBCO-B is Nonconductive of Electric Current

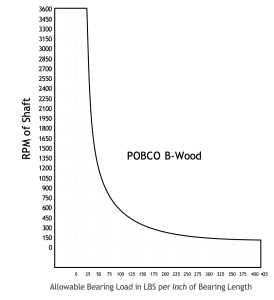

POBCO-B Bearing Lengths and Wall Thickness

Minimum bearing length and allowable bearing load per bearing are determined by using our bearing load curve. Since the lubricant blend is contained in the bearing wall, the thickness of the bearing wall should be equal to or greater than the recommended minimum wall thickness, as shown on the chart. In most instances shaft diameters cannot be decreased. Frequently, however, the diameter of the bearing housing can be increased to obtain at least the recommended minimum bearing wall.

| POBCO-B Shaft Diameter | Recommended Minimum Wall Thickness* |

| to 1/2” 1/2”-1” 1” to 1-1/2” 1-1/2” to 2” 2” to 2-1/2” 2-1/2” to 4” | 1/16”-1/8” 1/8”-3/16” 3/16”-5/16” 5/16”-3/8” 3/8”-1/2” 1/2”-5/8” |

*SATISFACTORY SERVICE CAN BE OBTAINED UNDER CERTAIN OPERATING CONDITIONS WITH WALL THICKNESS LESS THAN THOSE RECOMMENDED.

Shaft Selection

To maximize the life of the bearing it is important to use proper shafting. Overall, steels with a finish of 16 RMS are the preferred choice. Hardened shafts should be used in abrasive applications. Common shaft materials include: carbon steels, stainless steels, hard chromed steels and hard anodized aluminums.