Engineering Data

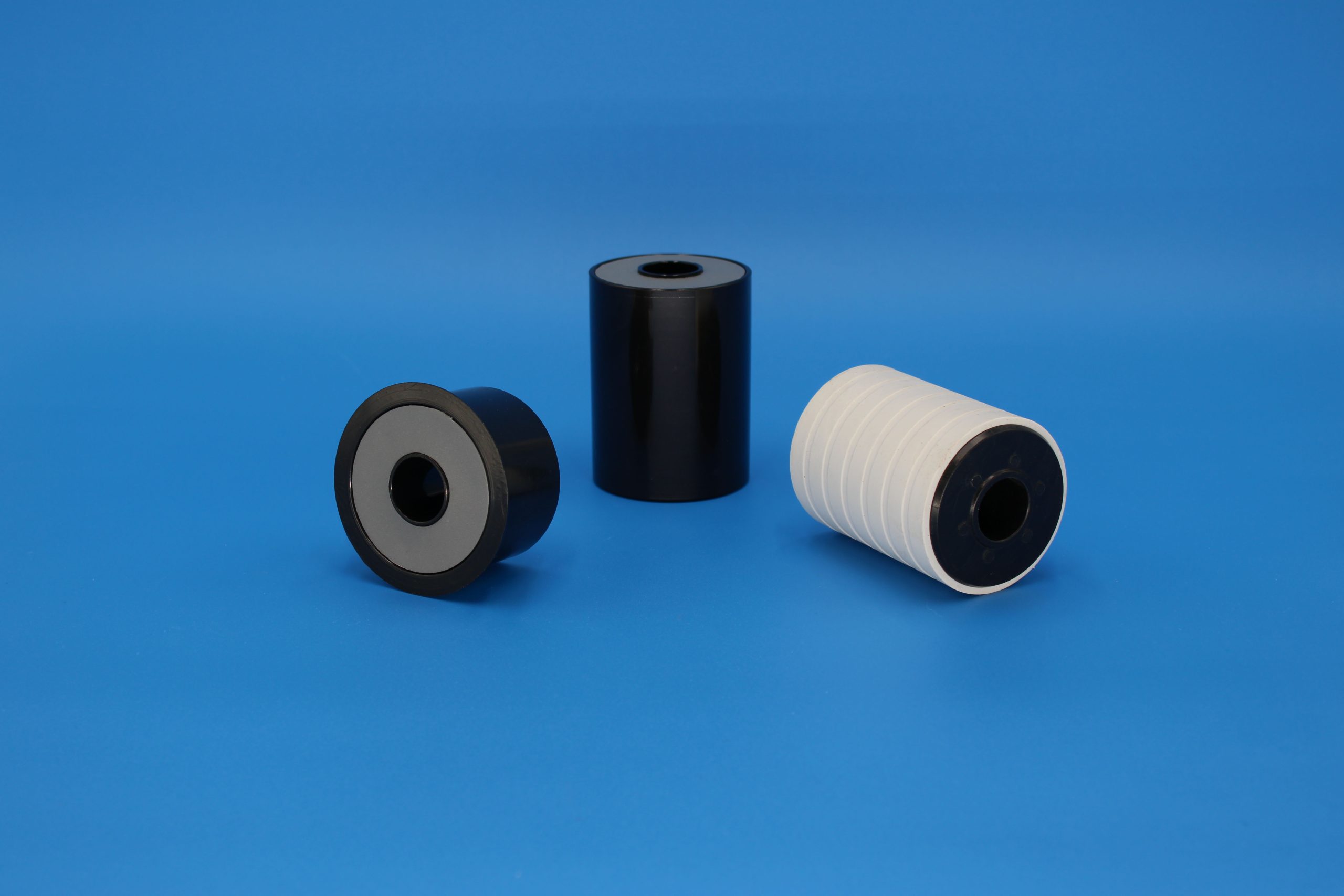

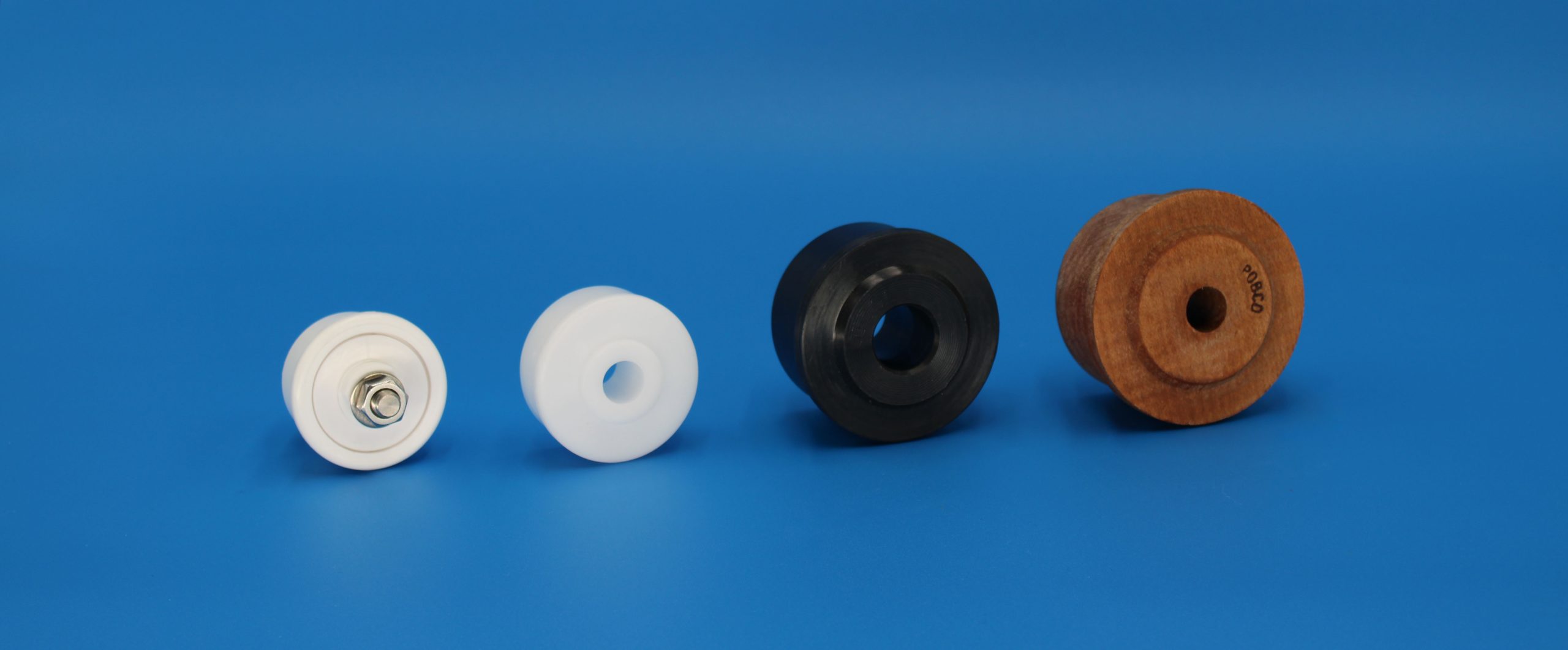

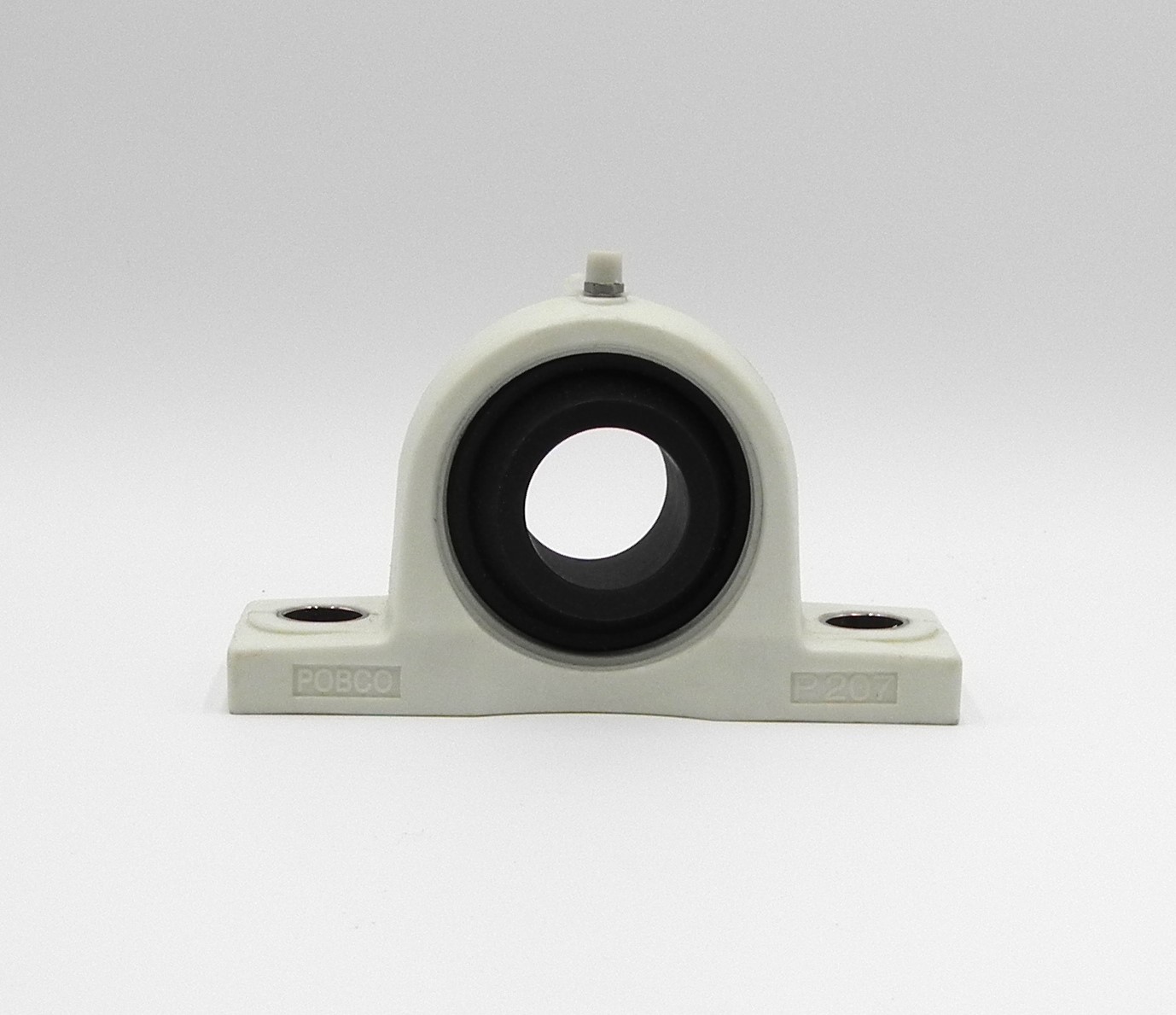

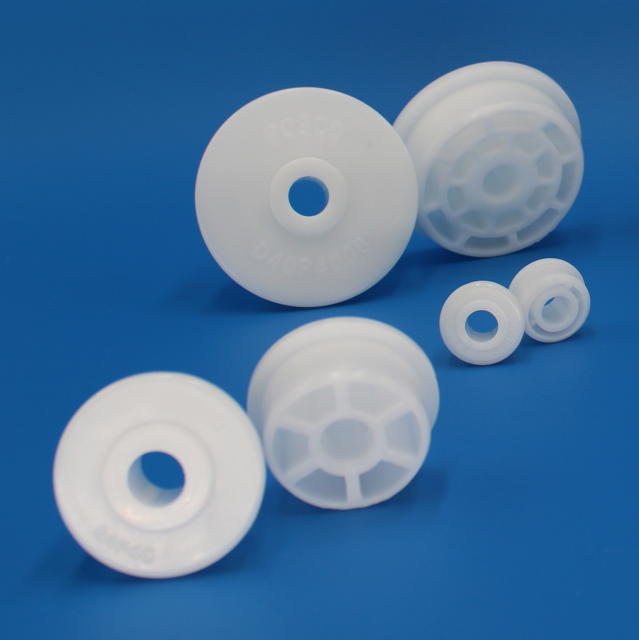

POBCO-B Wood Materials and POBCO Plastics

Bearing Clearances

POBCO bearings are normally furnished with an installed clearance between the bearing and its journal, as shown in the table below. This provides the proper running clearance under actual operating conditions. Bearings also can be furnished with no clearance when the user desires to ream after installation in housing. Reaming has no effect on the self-lubricating action of POBCO non-metallic bearings.

| SHAFT DIA. | CLEARANCE | |||

| BEARING OPERATING CONDITIONS | ROLL END OPERATING CONDITIONS | |||

| DRY | WET | DRY | WET | |

| to 1/2” | .002-.010 | .010-.030 | .015-.030 | .015-.045 |

| 1/2” to 1” | .004-.015 | .015-.040 | .015-.030 | .030-.055 |

| 1” to 1-1/2” | .006-.020 | .025-.050 | .015-.030 | .040-.060 |

| 1-1/2” to 3” | .010-.025 | .030-.060 | ||

| 3” or larger | .015-.030 | .030-.070 | ||

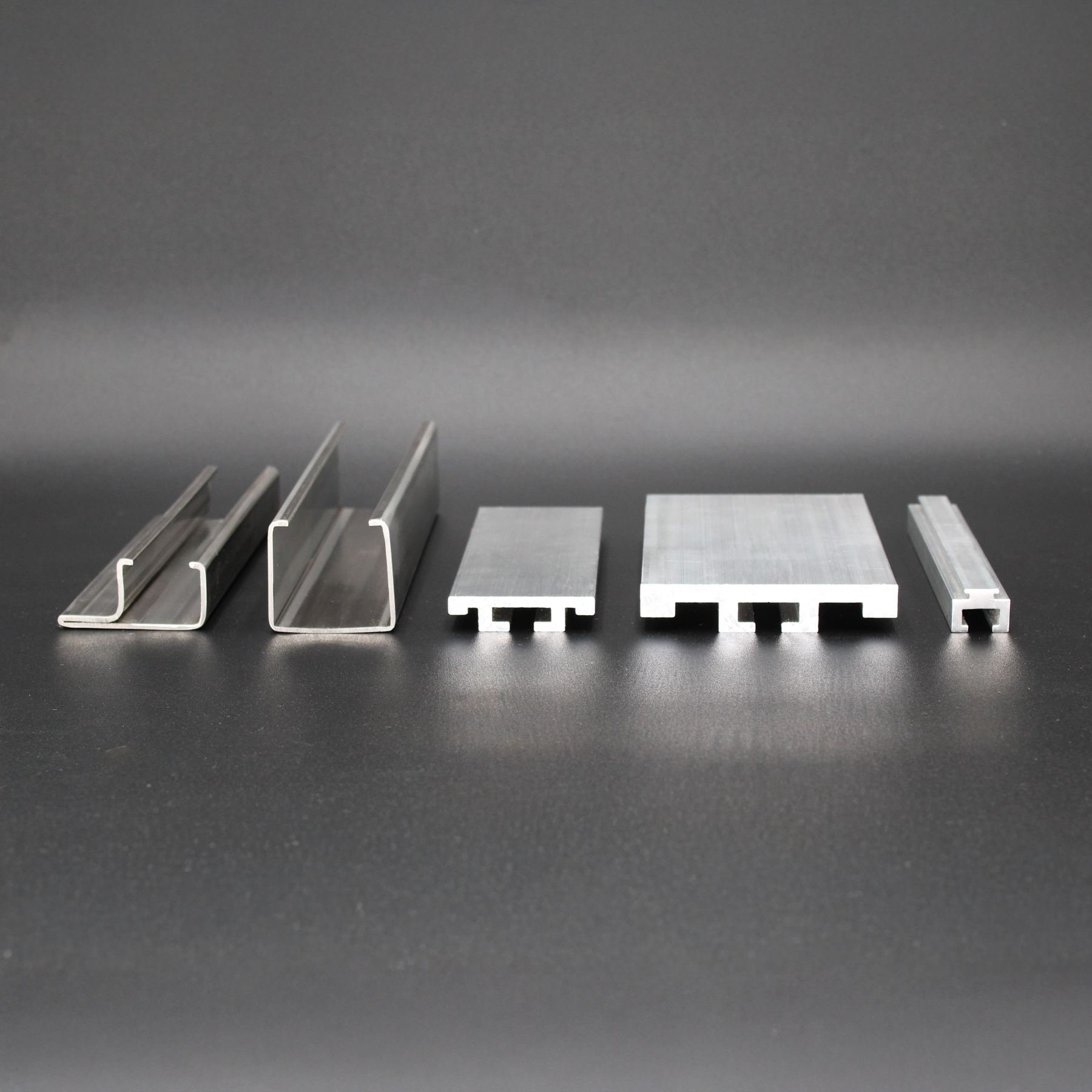

Press Fits

POBCO sleeve, flange and roll end bearings are normally furnished with oversize outside diameters to ensure firm retention in their housings, as shown in the table. The leading edge of the housing must be chamfered to prevent shearing the outside diameter of the bearing during installation.

Normal bearing tolerances are shown in the following table. Closer tolerances are available.

| Nominal OD | Press Fit |

| to 1/2” 1/2” to 1-1/2” 1-1/2” to 3” 3” and larger | .003-.006 .004-.008 .005-.010 .006-.012 |

Required Material Information

(For Bearings, Rectangular Wear Strip, Curved Wear Strip and Chain & Cable Guides) To signify POBCO materials add code letters before the first hyphen in the part number.

Examples:

- For POBCO-B (lubricant-filled hardwood) add B

- For POBCO Plus (fluid lube-filled UHMW) add P

- For POBCO UHMW add U

Required Bearing Information

To complete the bearing part number, indicate the bearing clearance by adding the appropriate suffix from the table below.

D-Dry operating condition clearance is standard for plastics only.

W-Wet operating condition clearance is standard for POBCO-B wood only.

N-No clearance (for reaming at installation)(for all materials)

Examples:

- Sleeve bearing 1/2” x 3/4” x 1-1/4” for dry operating conditions: SLB-0812020-D

- Flange bearing 5/8” x 1” x 1-1/2” no clearance (for installation): FLU-1016024-N

- Two piece spherical bearing, 62mm sphere, 1-1/4” shaft, wet operating conditions: PSBB-206228-TP-W

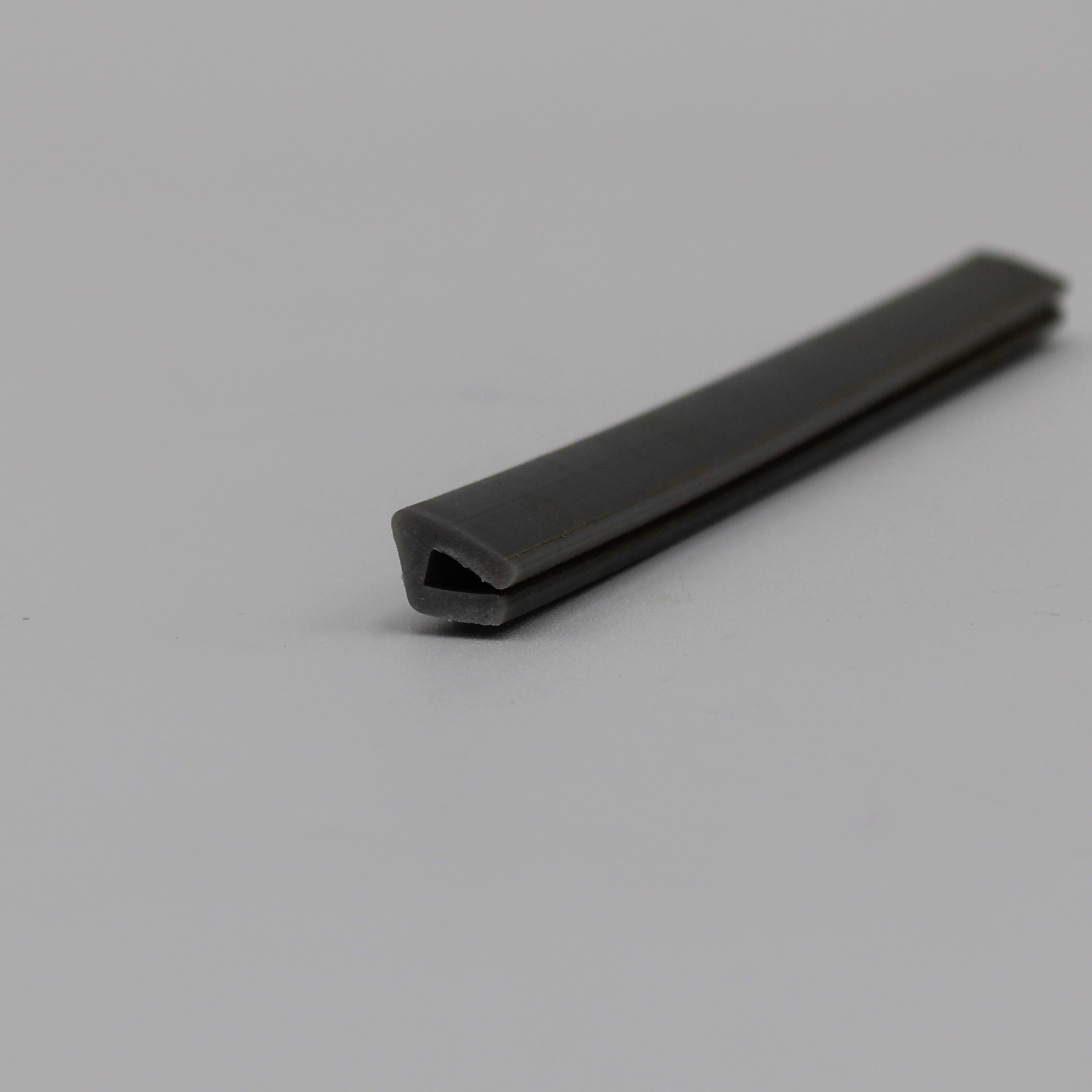

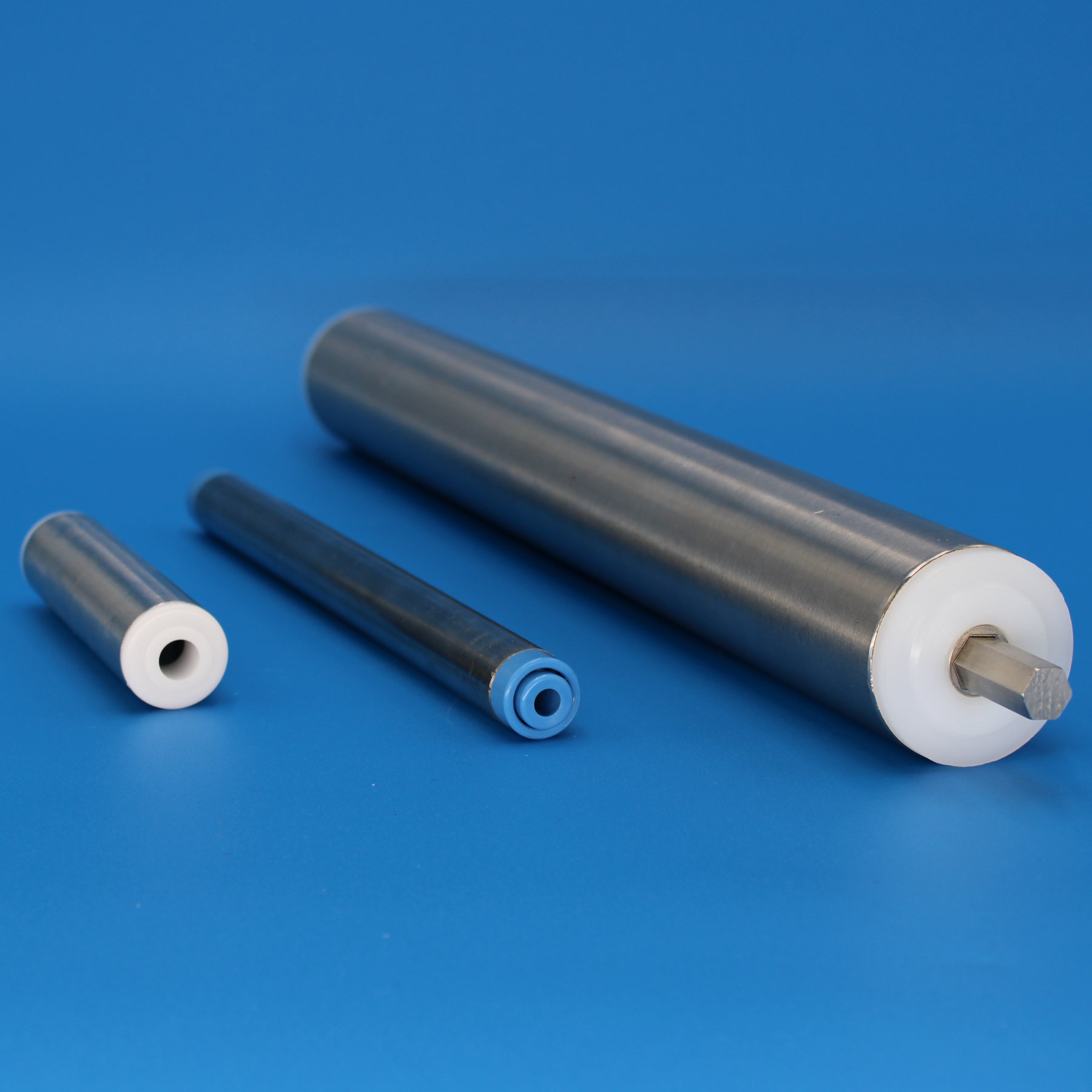

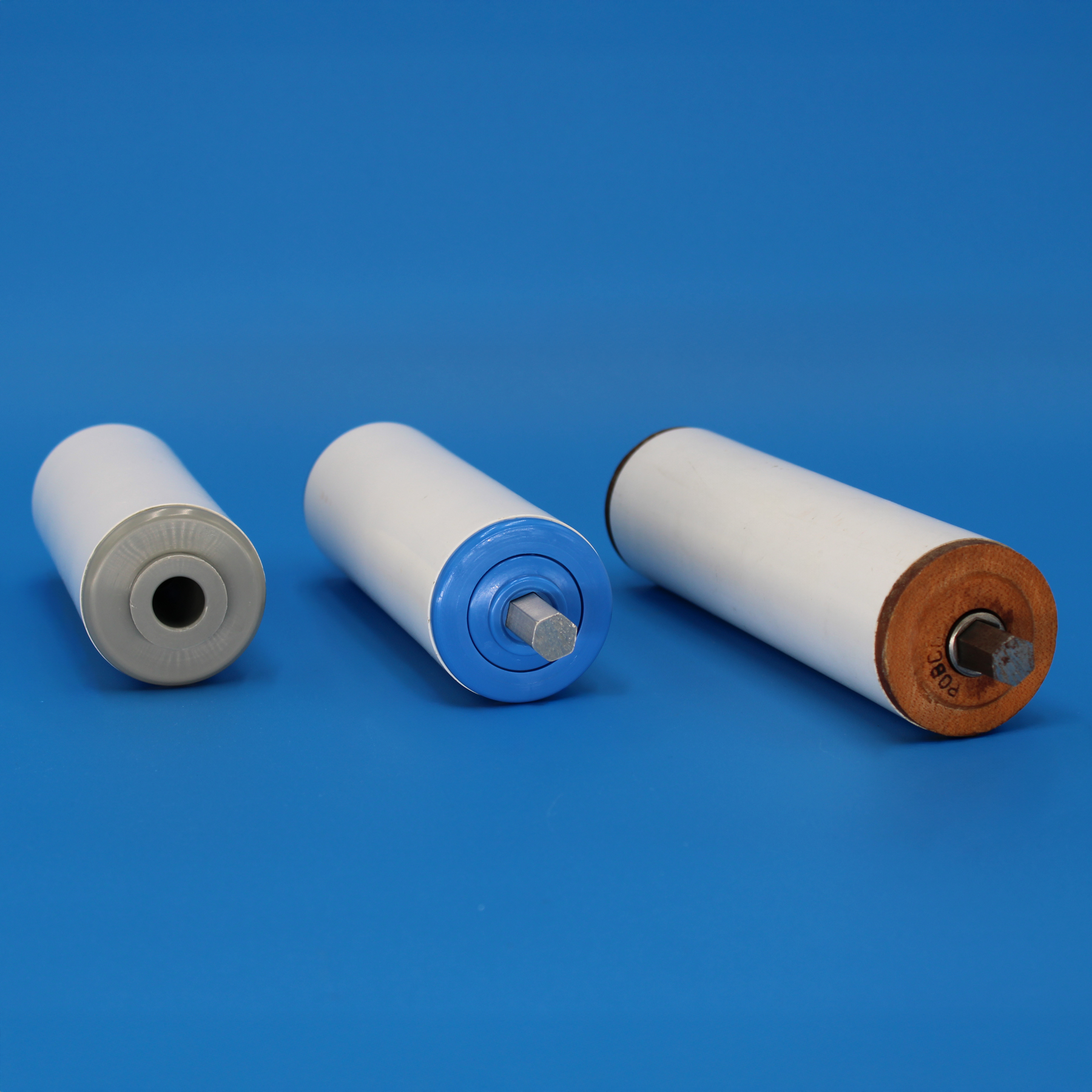

Roll End Bearings

To complete the roll end bearing or part number, add the shaft size in sixteenths (two digits) followed by the bearing clearance suffix. (1/2” shaft = 08, 3/4” shaft = 12)

Examples:

- Standard roll end bearing for 2-1/2” diameter 16 gauge tubing with 5/8” shaft: STP-40T16-10

- Blind-bore roll end bearing for 2” schedule 40 PVC pipe with 9/16” shaft operating in a wet condition: BLB-32P40-PVC-09W

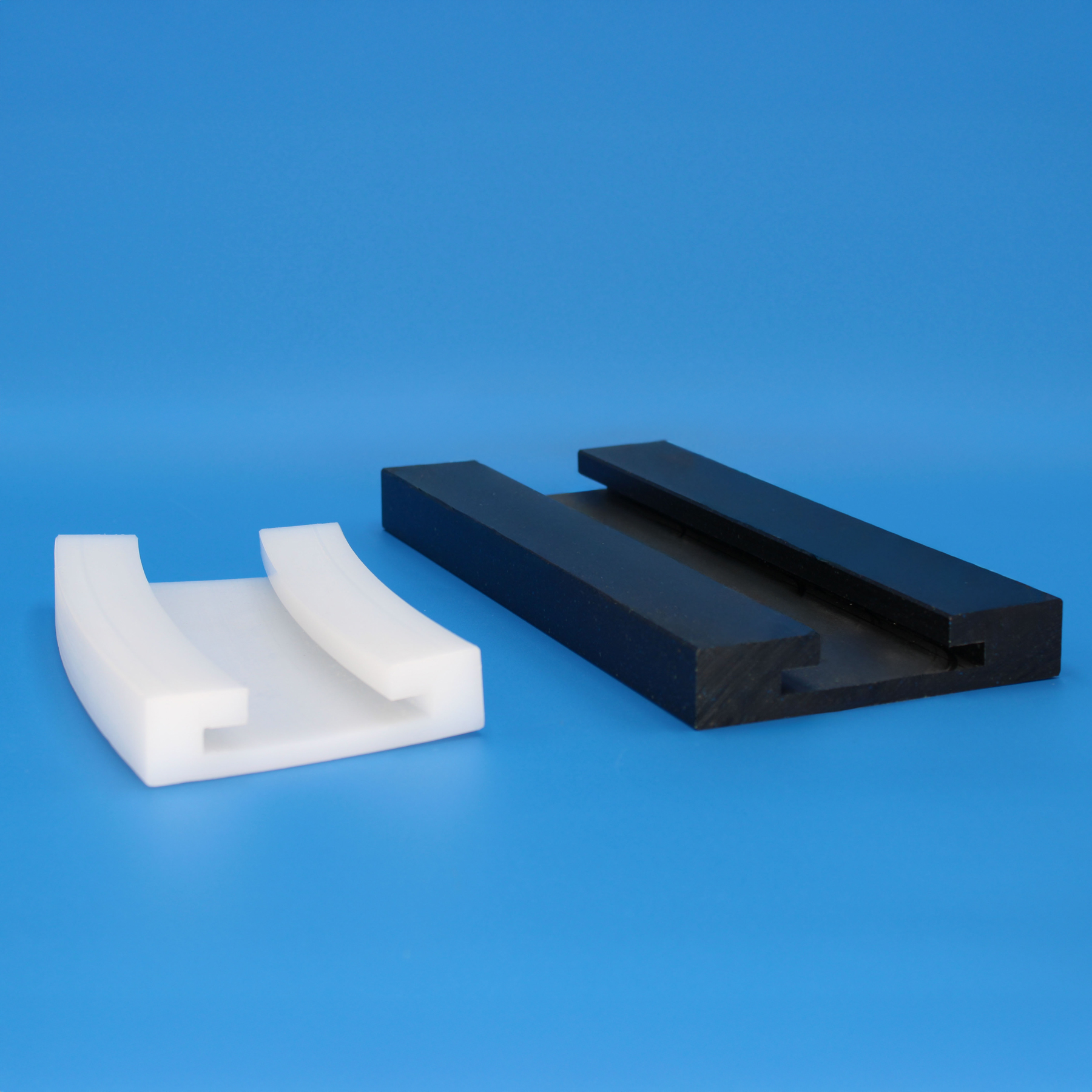

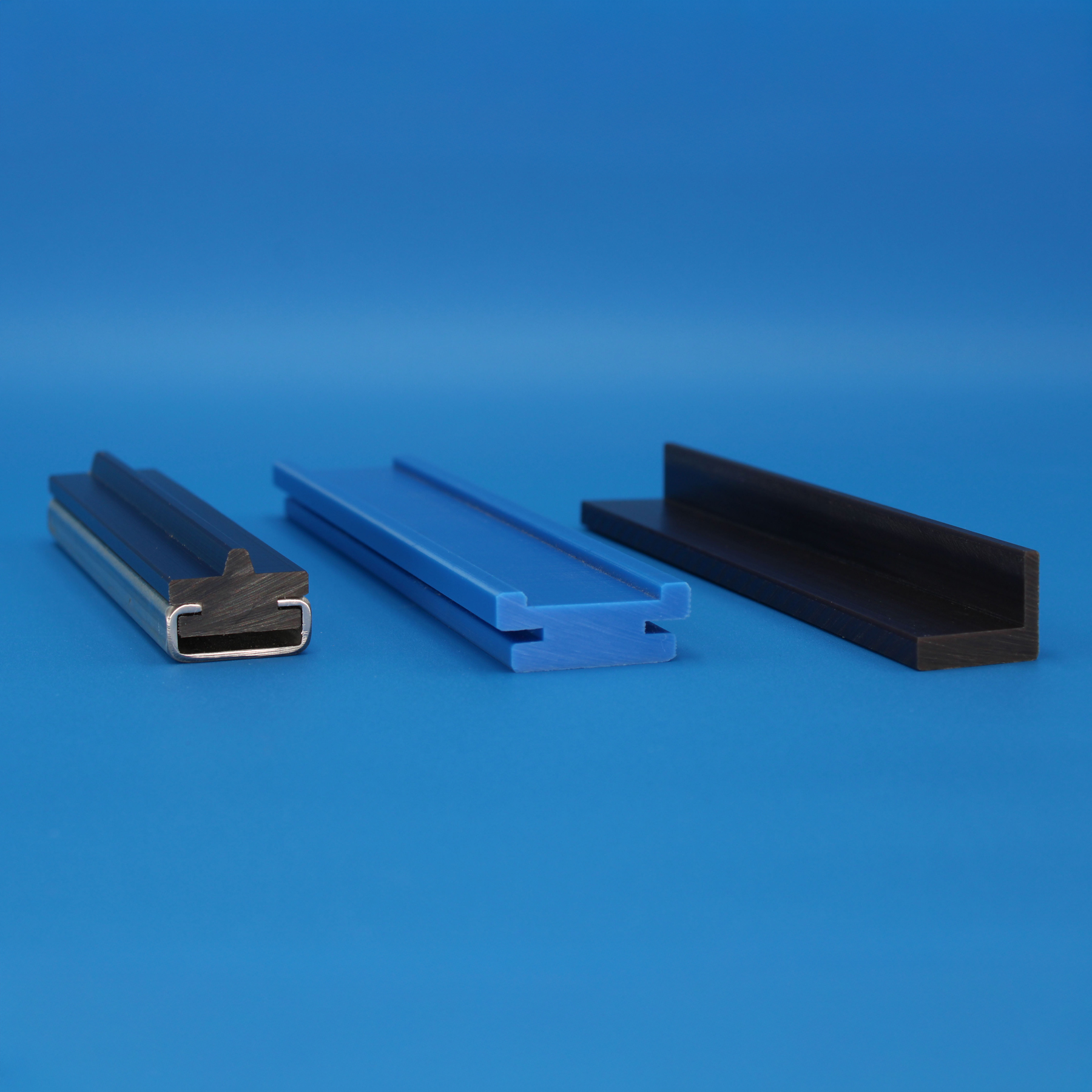

Wear Strip Tolerances

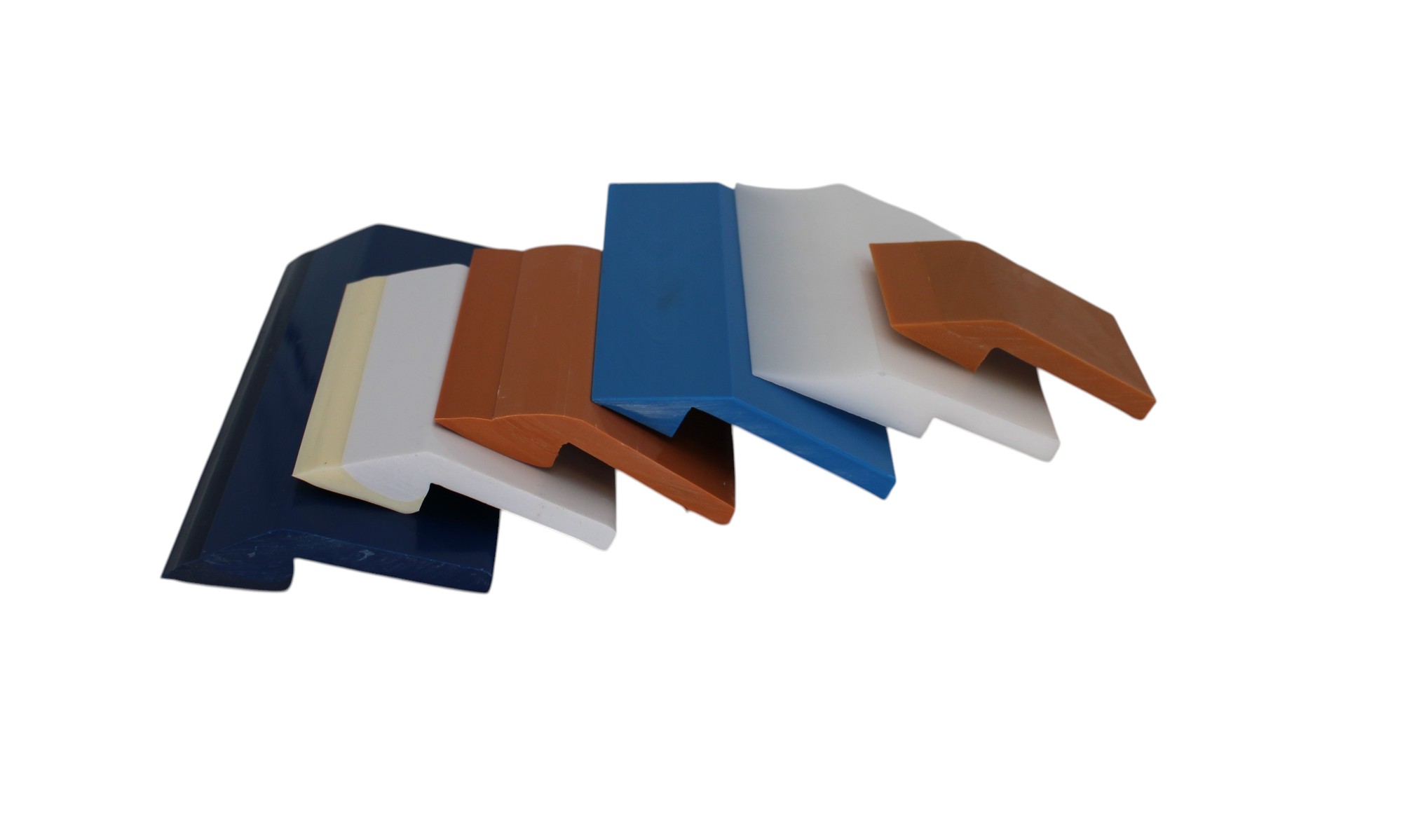

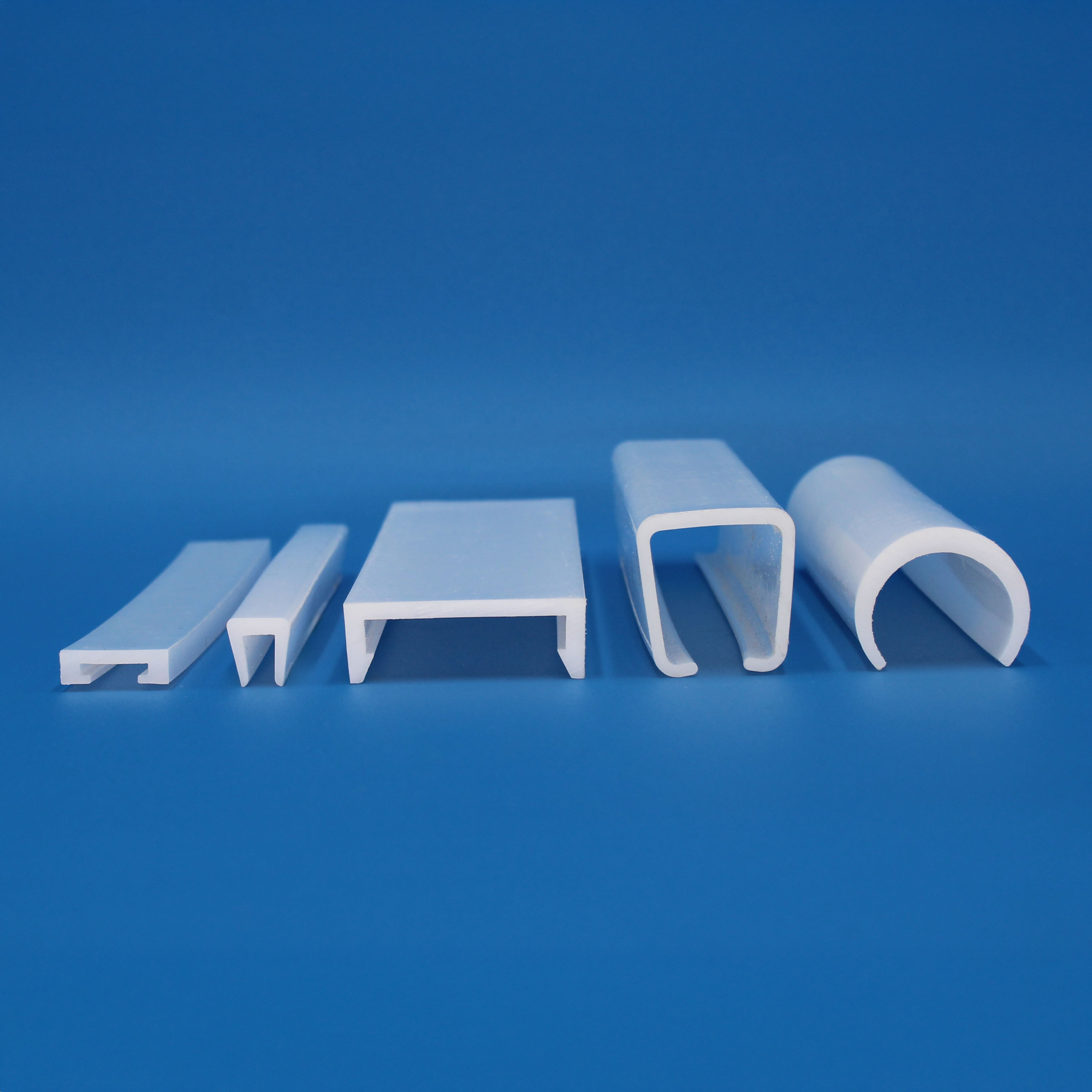

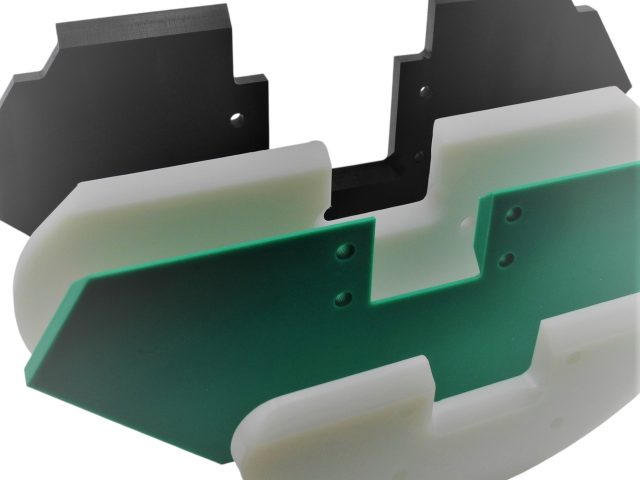

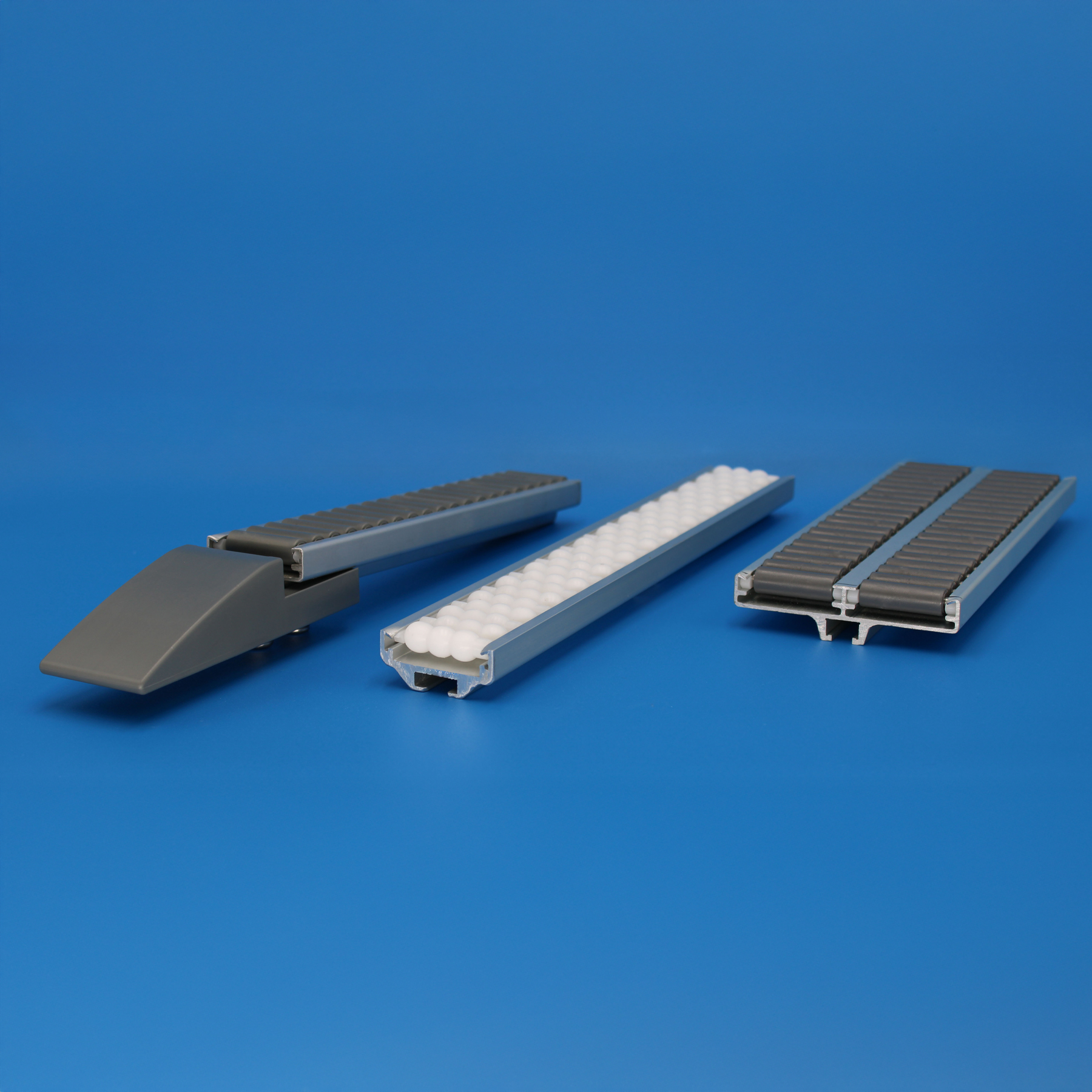

POBCO UHMW, POBCO plus, and POBCO-B Hardwood

| Normal Commercial Tolerances Thickness | Normal Machined Tolerances Thickness |

| 1/8”-3/16” +/- 15% 1/4”-3/8” +/- 10% 1/2” & over +/- 10% Width: +/- .030” Length: -1/2”+1” | 1/8”-3/8” +/- .020” 1/2” & over +/- .010” Width: +/- .010” Length: +/- .030 |

CLOSER TOLERANCES ARE AVAILABLE. FOR OTHER MATERIAL TOLERANCES, PLEASE INQUIRE. PLEASE SPECIFY COMMERCIAL OR MACHINED OR OTHER TOLERANCES.

Required Wear Strip Information

To complete the wear strip part number, add the length in inches as shown by the examples below:

- Rectangular wear strip 1/2” thickness x 2” width x 60” length: WSB-0832L60

- Chain Guide, Profile 2, 2060 chain, 120” length:P2P-2060L120

Allowances must be made to eliminate the possibility of binding caused by machine and material expansion when designing wear strip.

Wood and Engineering Data

POBCO-B Physical Properties (Lubricant-Filled Hardwood)

| Density (lbs/in3) Coefficient of Friction Temperature Range Specific Gravity Lubricant Content by Weight Load Weight (continuous duty) |

.038 .07-.112 -50o to 180o 1.2 40% 1000 psi |

Tensile Strength Permanent Deformation (7500 psi compression) Coefficient of Thermal Expansion (per oF) PV Factor (continuous duty) Wear Rate Factor |

1100 psi .005 set 4.3 x 10-6 12,000 psi-fpm <0.1×10-10 (inch) PV x hr. |

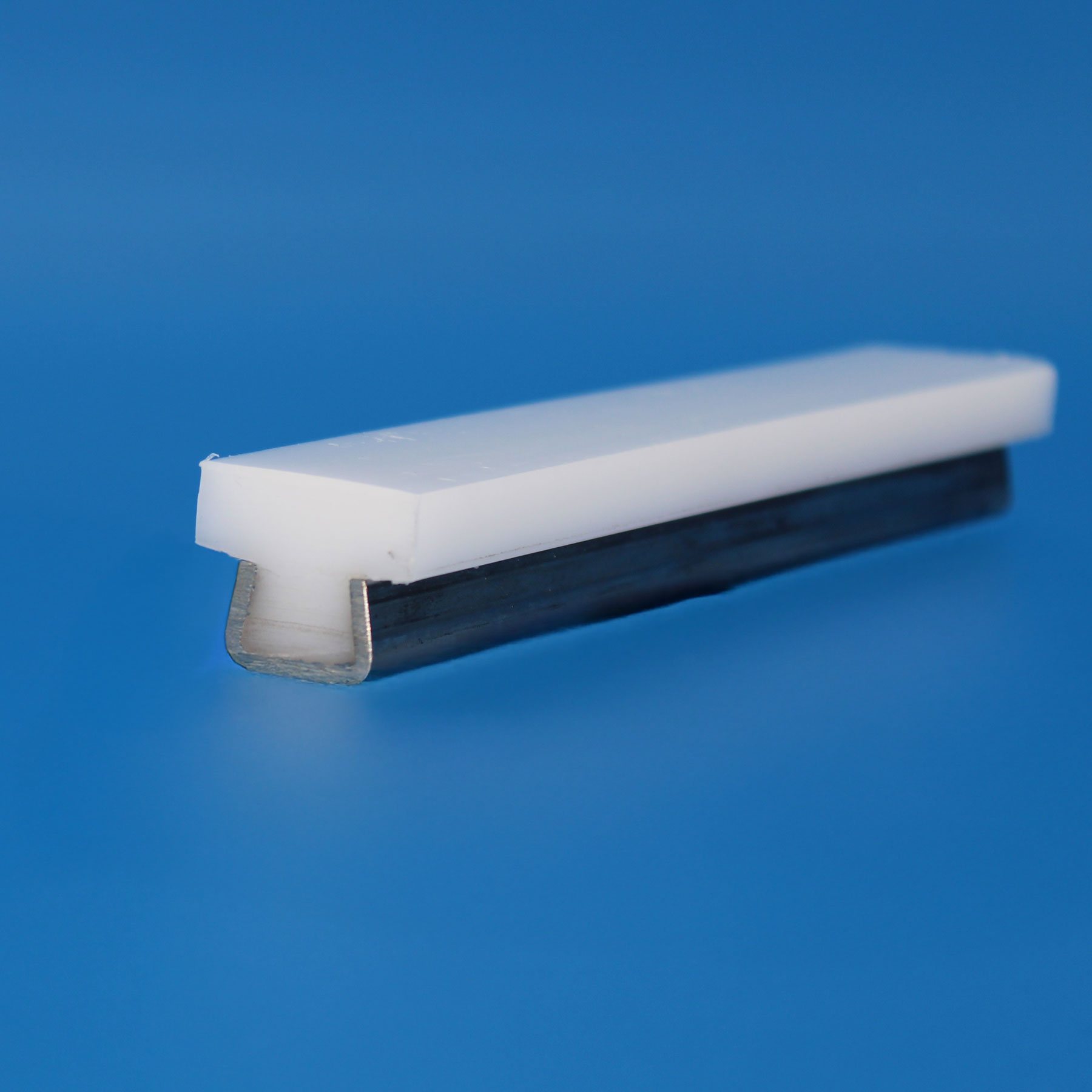

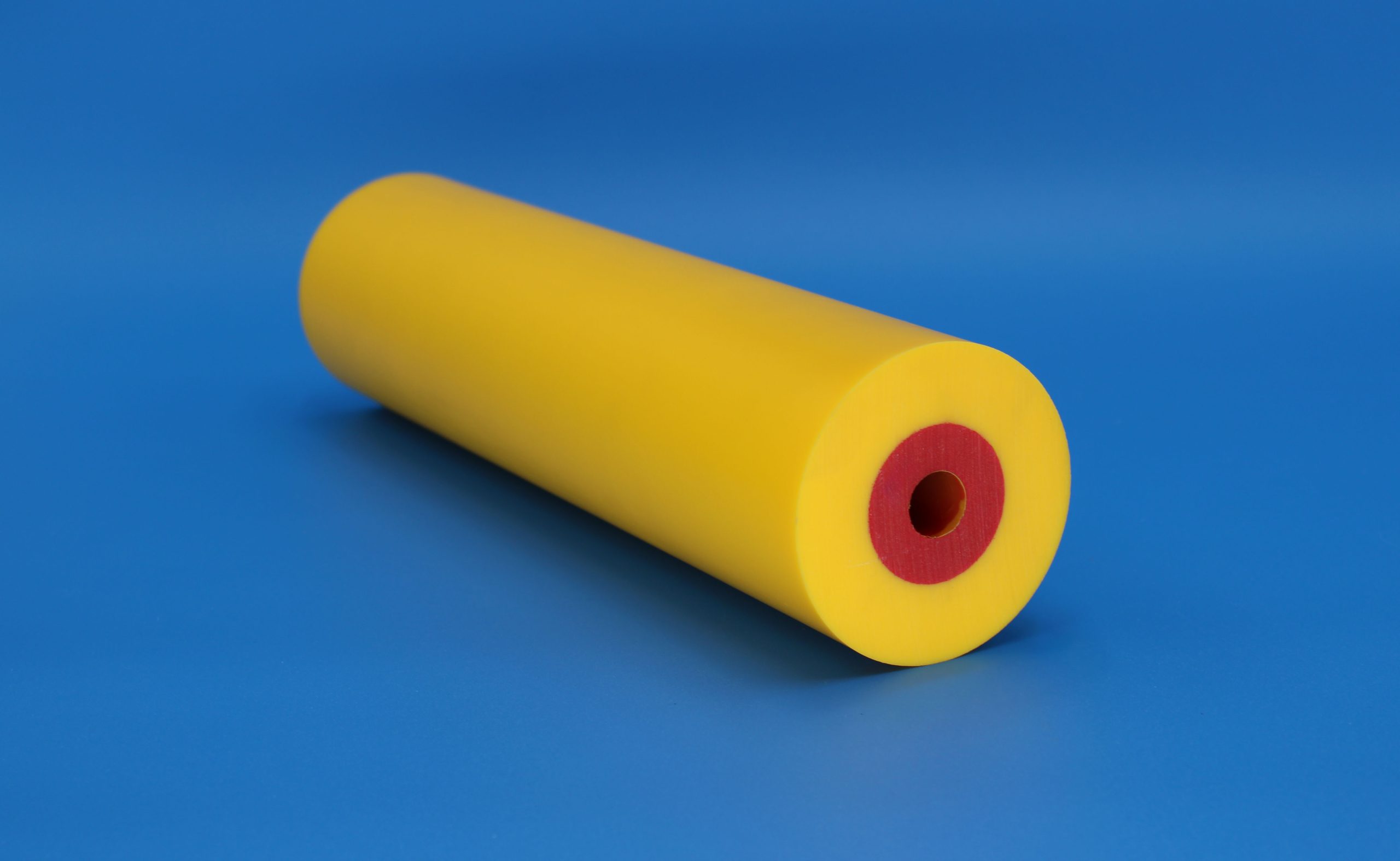

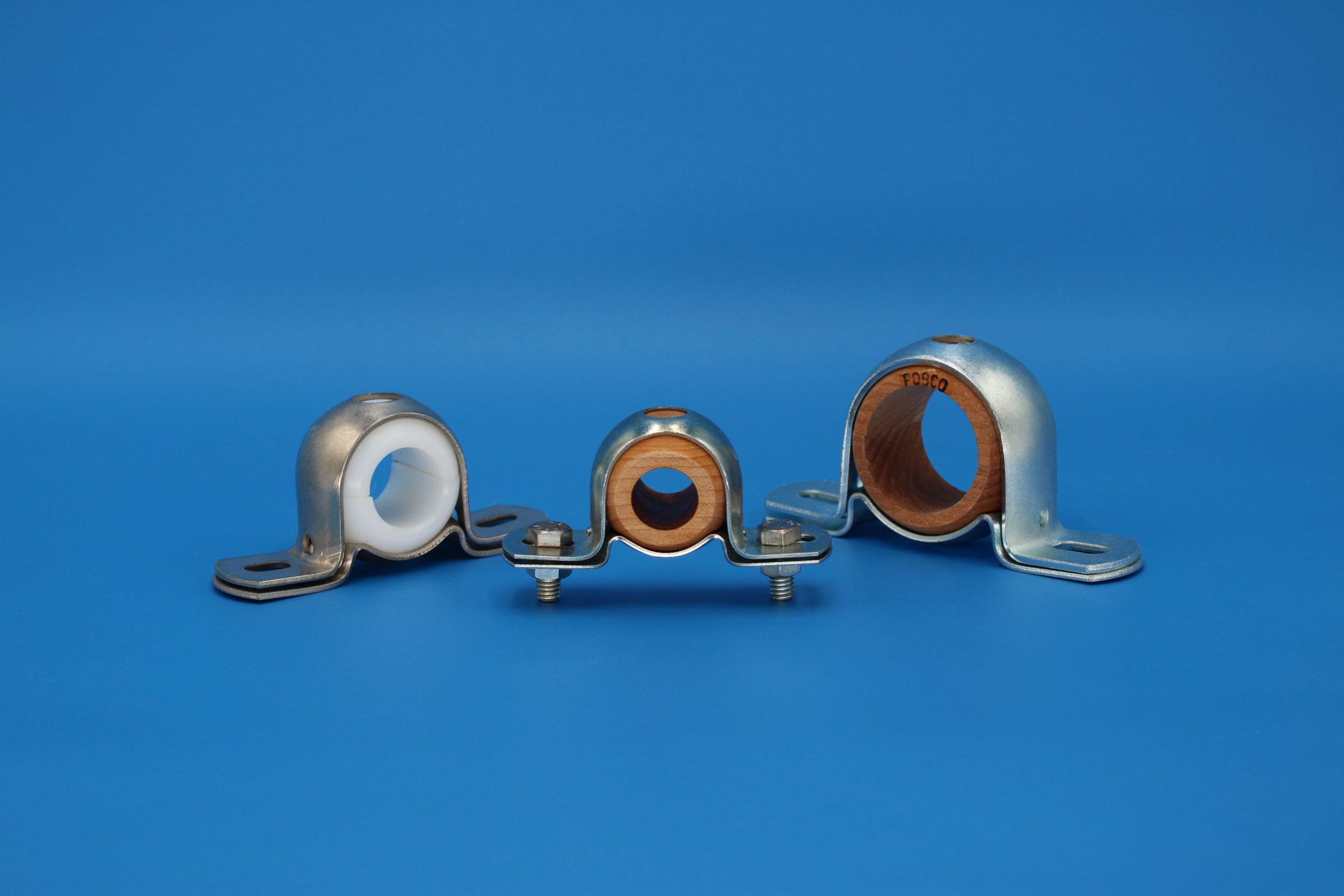

POBCO-B Bearings and Wear Strips

Our exclusive lubricant blend is impregnated into 100 percent of the hardwood, producing POBCO-B material from which the bearings & wear strips are manufactured. The lubricant on the bearing surface provides a low friction film for initial start-up. During operation, additional lubricant is drawn to the bearing surface in a controlled flow to maintain a continuous film between the journal or chain and the bearing. The flow constantly adjusts itself based on load, speed, and the requirements of the operation. When motion ceases, the bearing reabsorbs the lubricant. Reaming does not seal off the self- contained lubricants.

POBCO-B is Nonconductive of Electric Current

POBCO-B Bearing Lengths and Wall Thickness

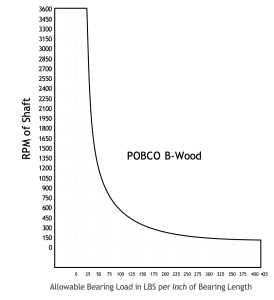

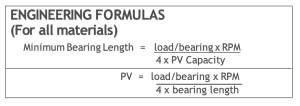

Minimum bearing length and allowable bearing load per bearing are determined by using our bearing load curve. Since the lubricant blend is contained in the bearing wall, the thickness of the bearing wall should be equal to or greater than the recommended minimum wall thickness, as shown on the chart. In most instances shaft diameters cannot be decreased. Frequently, however, the diameter of the bearing housing can be increased to obtain at least the recommended minimum bearing wall.

| POBCO-B Shaft Diameter |

Recommended Minimum Wall Thickness* |

| to 1/2” 1/2”-1” 1” to 1-1/2” 1-1/2” to 2” 2” to 2-1/2” 2-1/2” to 4” |

1/16”-1/8” 1/8”-3/16” 3/16”-5/16” 5/16”-3/8” 3/8”-1/2” 1/2”-5/8” |

*SATISFACTORY SERVICE CAN BE OBTAINED UNDER CERTAIN OPERATING CONDITIONS WITH WALL THICKNESS LESS THAN THOSE RECOMMENDED.

Shaft Selection

To maximize the life of the bearing it is important to use proper shafting. Overall, steels with a finish of 16 RMS are the preferred choice. Hardened shafts should be used in abrasive applications. Common shaft materials include: carbon steels, stainless steels, hard chromed steels and hard anodized aluminums.

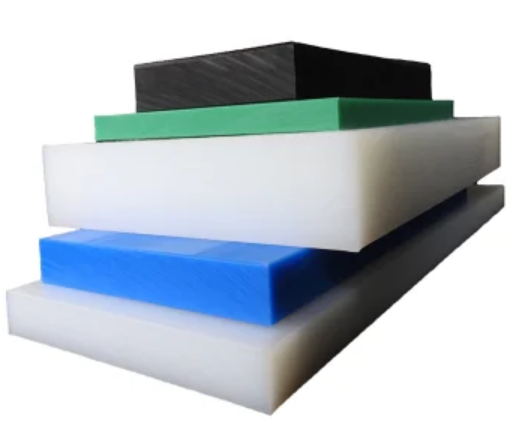

Properties of POBCO Materials

|

ENGINEERING DATA |

POBCO-B

HARDWOOD |

UHMW | LUBE-FILLED UHMW PLUS® |

REPRO UHMW |

(7) HI-TEMP. UHMW |

(13) HI-WEAR UHMW |

DRYWEAR UHMW |

(11) NYWEAR | NYLON | (10)

NYLON MD |

|

| CODE LETTERS | B | U | P | UR | UH | CP | DW | NW | N | MD | |

| P.V. Cap psi-fpm (1) | 12,000 | 2,000 | 12,000 | 2,000 | 2,000 | 2,300 | 4,000 | 16,000 | 2,500 | 3,500 | |

| Max. Surface Speed fpm | 500 | 100 | 300+ | 100 | 100 | 100 | 150 | 150 | 100 | 150 | |

| Static Load Cap. psi | 1,000 | 1,000 | 600 | 900 | 1,000 | 1,000 | 1,000 | 1,000 | 1,000 | 1,000 | |

| Service Temp. Range (2)oF | 180 | 180 | 165 | 180 | 275 | 200 | 180 | 230+ | 220 | 220 | |

| Coef. of Friction Ave. | .09 | .15-.20 | .06-.12 | .15-.20 | .15-.20 | .16-.18 | .15 | .15 | .19 | .17 | |

| Abrasion Resistance (3) | 1-3 | 1-2 | 1-2 | 1-2 | 1-2 | 1 | 1-2 | 3 | 3 | 3 | |

| Dim. Stability in Water | Fair | Exc. | Exc. | Exc. | Exc. | Exc. | Exc. | Good | Fair | Fair | |

| USDA/FDA Compliant | Indirect | yes | yes | no | yes | no | no | yes* | yes | no | |

| Chemical Resistance at 73o F* | |||||||||||

| Acid Weak | A | A | A | A | A | A | A | A | A | A | |

| Acid Strong | L | L | L | L | L | A | L | U | U | U | |

| Alkalies Weak | A | A | A | A | A | A | A | A | A | A | |

| Alkalies Strong | L | A | A | A | A | A | A | A | A | A | |

| Hydrocarbon Aromatic | – | L | L | L | L | A | L | A | A | A | |

| Hydrocarbon Aliphatic | – | A | A | A | A | A | A | A | A | A | |

| Ketones | – | A | A | A | A | A | A | A | A | A | |

| Ethers | – | A | A | A | A | A | A | A | A | A | |

| Alcohols | – | A | A | A | A | A | A | A | A | A | |

| Inorganic Salt Solution | A | A | A | A | A | A | A | A | – | A | |

| Continuous Sunlight | A | U** | L | L | L | A | L | L | L | L | |

| Standard Color | Brown | White | Grey/Brown | Black/Green | White | Black/Green | Black | Natural | White/Grey | Black | |

| Low Temp oF* | – | -200 | – | -200 | – | – | -10 | -10 | -10 | ||

| ENGINEERING DATA | ACETAL DELRIN® |

(8) ACETAL AF |

VIRGIN PTFE |

GLASS FILLED PTFE |

POBLON | RULON® 641 | RULON® LR BEARING GRADE |

ERTALYTE® | UNFILLED PEEK |

| CODE LETTERS | D | DT | T | GT | TM | RF | RB | YT | PK |

| P.V. Cap psi-fpm (1) | 2,000 | 8,000 | 1,000 | 10,000 | 10,000 | 10,000 | 10,000 | 2,800 | 14,000 |

| Max. Surface Speed fpm | 100 | 150 | 100 | 400 | 400 | 400 | 400 | 125 | 100 |

| Static Load Cap. psi | 2,000 | 2,000 | 400 | 800 | 1,000 | 1,000 | 1,000 | 2,000 | 6,000 |

| Service Temp. Range (2)oF | 180 | 200 | 450 | 500 | 500 | 550 | 550 | 210 | 480 |

| Coef. of Friction Ave. | .22 | .08-.14 | .06-.15 | .10-.13 | .10-.30 | .10-.30 | .15-.25 | .20 | .20 |

| Abrasion Resistance (3) | 5 | 1-2 | 5 | 1-2 | 1-2 | 1-2 | 1-2 | 3 | 1-2 |

| Dim. Stability in Water | Good | Good | Exc. | Exc. | Exc. | Exc. | Exc. | Good | Exc. |

| USDA/FDA Compliant | yes | maybe | yes | no | Yes | yes | no | yes | yes |

| Chemical Resistance at 73oF* | |||||||||

| Acid Weak | A | S | A | A | A | A | A | A | A |

| Acid Strong | U | U | A | A | A | A | A | L | L |

| Alkalies Weak | A | A | A | A | A | A | A | A | A |

| Alkalies Strong | U | U | A | A | A | A | A | U | A |

| Hydrocarbon Aromatic | A | A | A | A | A | A | A | A | A |

| Hydrocarbon Aliphatic | A | A | A | A | A | A | A | A | A |

| Ketones | A | A | A | A | A | A | A | L | A |

| Ethers | A | A | A | A | A | A | A | A | A |

| Alcohols | A | A | A | A | A | A | A | A | A |

| Inorganic Salt Solution | – | A | A | A | A | A | A | A | A |

| Continuous Sunlight | U | L | A | A | A | A | A | A | – |

| Standard Color | White | Brown | White | White | White | White | Maroon | White | Beige |

| Low Temp oF* | -40 | -40 | -200 | -200 | -400 | -200 | -200 | – | – |

#1 At Room Temperature

#2 At Low PV Levels

#3 Rating 1 (Excellent) to 5 (Fair)

#5 A=Acceptable L=Limited U=Unacceptable

#7 Thermal Expansion Is Up To 25% Less Than Normal

UHMW with extended wear life

#8 PTFE-Filled Acetal

#10 Moly-Filled Nylon

#11 Lube-Filled Nylon – Bearing Grade Green, FDA

Compliant Off White

#12 Green & Black Reprocessed UHMW

#13 33% More Wear Resistant than unfilled UHMW